There’s a good chance that the synthetic fibers in your running shorts, rain jacket, or backpack started life in a very different form — a single-use bottle, a carpet tile, maybe even a ghost net drifting in the Pacific.

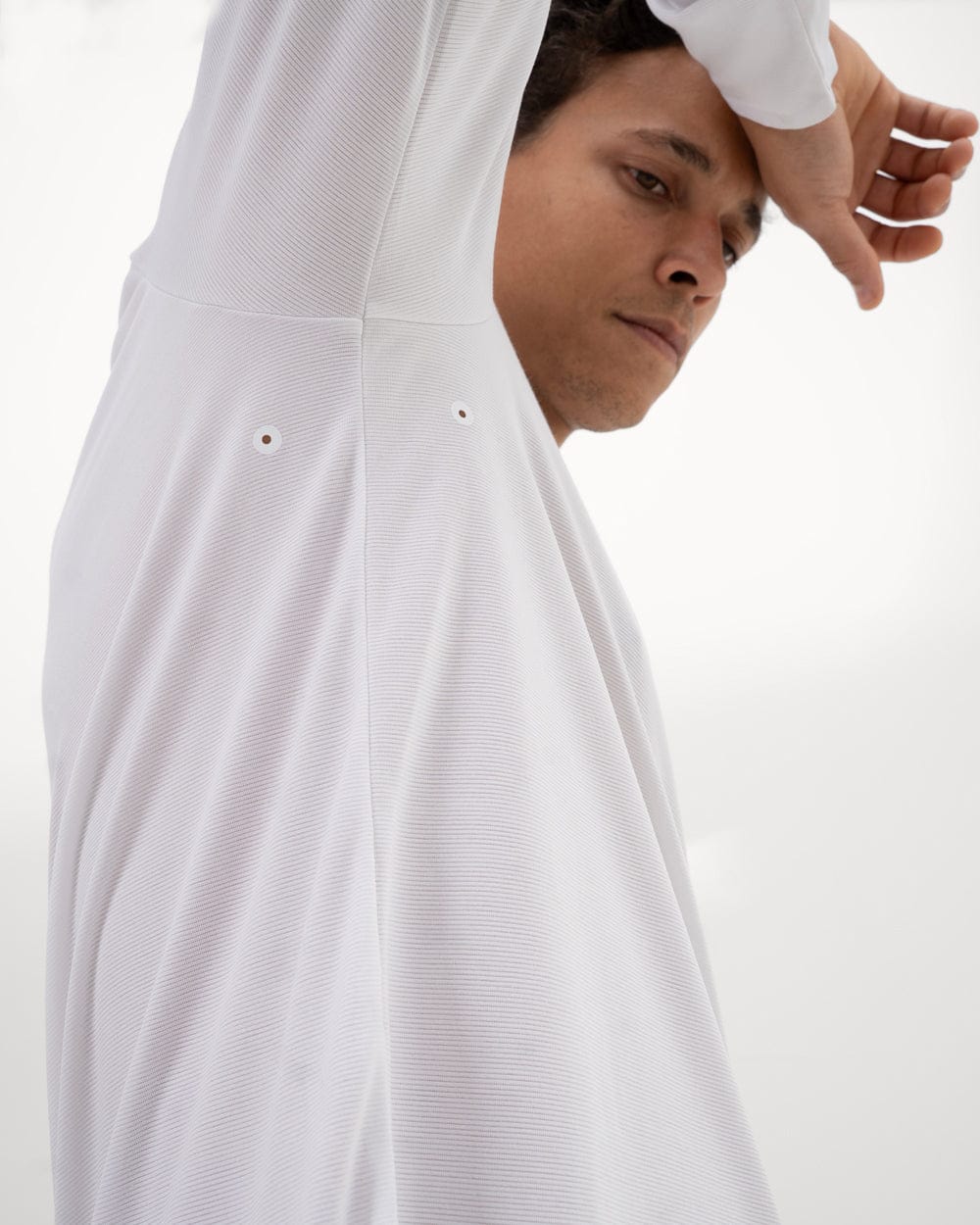

Polyester and nylon dominate the textile industry. They’re durable, lightweight, high-performance — and nearly always made from petrochemicals. Polyester alone accounts for nearly 60% of global fiber production. The environmental cost of producing these materials is steep, and as a design-driven technical brand, we think a lot about how to reduce that footprint.

Recycling synthetic yarns — both before and after they’ve been used — is one of the most impactful ways to cut waste and carbon emissions. But not all recycling is created equal. In this piece, we’re exploring the two key types of recycled synthetics: pre-consumer and post-consumer.

Pre-consumerwaste is the stuff that never made it out of the factory. Think PET plastic scraps trimmed from production lines, miscolored yarn batches, or fabric offcuts. It’s clean, uniform, and relatively easy to recycle — and in many cases, it would’ve been reused anyway as part of internal waste-reduction processes.

Post-consumer waste, on the other hand, comes after a product’s useful life. It includes plastic bottles tossed in a recycling bin, worn-out carpets, or discarded fishing nets retrieved from the ocean. It’s messier, harder to collect, and more expensive to process — but also far more impactful.

Both types reduce the need for virgin plastic, but their environmental value is not the same.Pre-consumer recycling is essentially a closed loop within the factory — efficient, but limited in scope. Post-consumer recycling addresses the broader issue: the overwhelming volume of plastic and synthetic textile waste already in circulation. It takes materials that would otherwise sit in landfills, break into microplastics, or pollute marine ecosystems, and transforms them into something purposeful.

That’s why many sustainability experts consider post-consumer recycled materials the gold standard — they clean up what’s already out there.

From a performance standpoint, there’s no difference. Recycled polyester and nylon — whether pre- or post-consumer — are chemically identical to virgin fiber. They offer the same durability, stretch, and technical function. The difference is environmental. Yet despite their potential, less than 1% of used clothing is recycled into new garments — a figure that, surprisingly, hasn’t changed much in recent years [European Parliament].

It’s a stark reminder that while recycled synthetics are a step forward, we’re still in the early stages of building a truly circular system. There’s enormous opportunity for innovation — not just in materials, but in how we collect, process, and design for recyclability from the start.

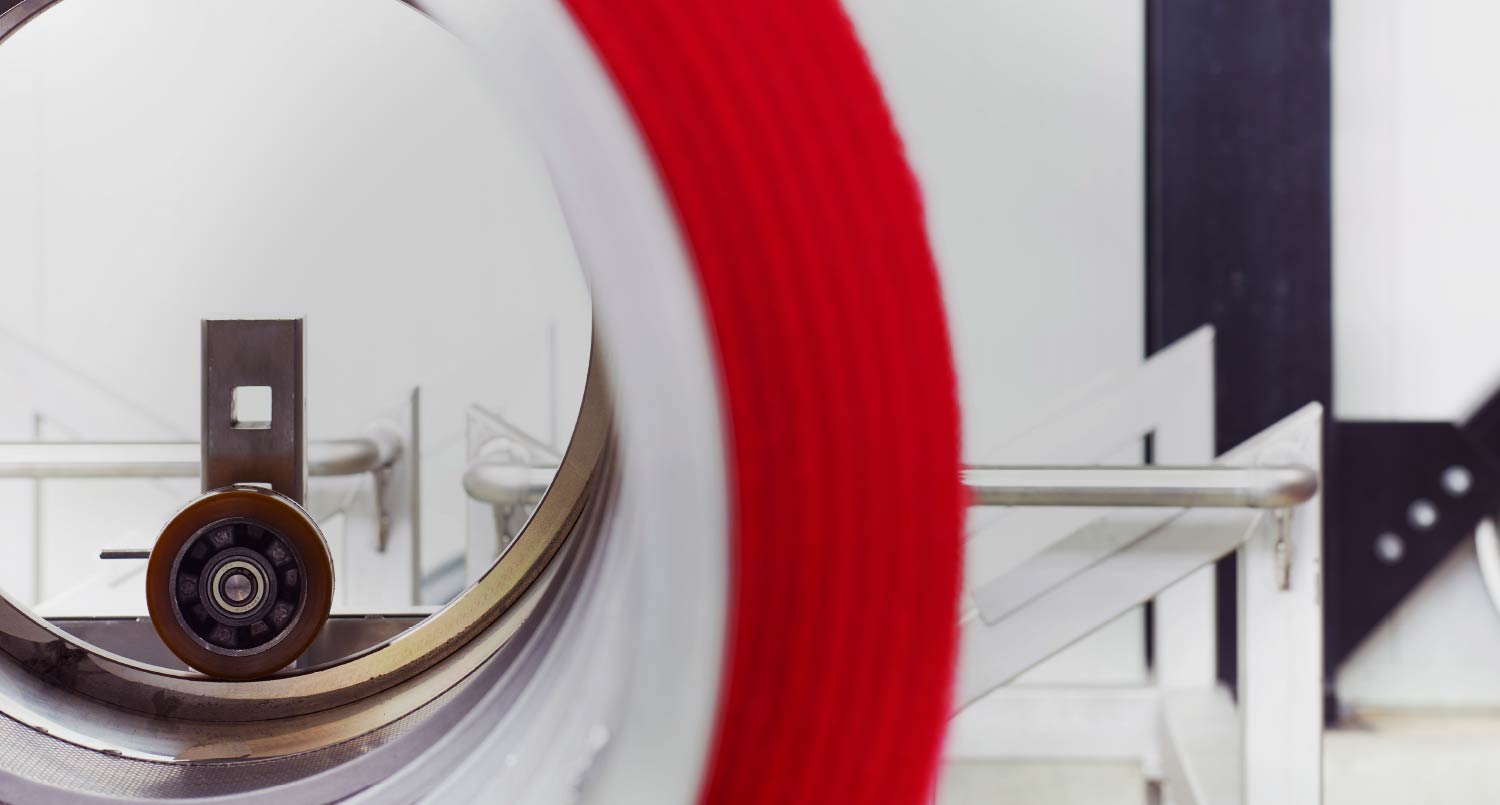

Recycling synthetic fibers is equal parts industrial alchemy and logistical precision. There are two general methods: mechanical recycling (melting and re-spinning plastic) and chemical recycling (breaking polymers down to molecular building blocks and starting over).

Recycled Polyester (rPET)

Most recycled polyester starts with PET bottles — clear, lightweight, and widely collected.

- Collection & Sorting: Bottles are sorted by color and type. Caps and labels are removed, often using water flotation and infrared sorting.

- Cleaning & Flaking: The bottles are washed, chopped into flakes, and stripped of any residue or adhesive.

- Melting & Extrusion:The flakes are melted and pushed through spinnerets to create filaments — essentially the same process as making virgin fiber.

- Yarn Formation: The filaments are stretched, textured, and spun into yarns that can be knit or woven into technical fabrics.

From there, the recycled polyester behaves just like its virgin counterpart — but with a much smaller footprint. Hit this link to see a video of the process.

Recycled Nylon

Nylon comes in multiple forms (nylon-6, nylon-6,6) and is found in everything from carpet to fishing nets. Recycling it is more complex.

- Mechanical recycling works when the nylon waste is clean and uniform — often pre-consumer scraps that can be melted and re-extruded.

- Chemical recycling is used for post-consumer waste like fishing nets or carpets. Here, nylon-6 is broken down into its base monomer, caprolactam, and then rebuilt into new nylon polymer — identical in quality to virgin fiber.

Companies like ECONYL® and NetPlus® have built entire supply chains around this approach. In the case of ECONYL, the impact is measurable: up to 80% lower global warming potential than virgin nylon, and a significant reduction in crude oil use.

Recycling synthetic fibers yields substantial environmental gains.

- Energy and Emissions: Recycling avoids the oil extraction and polymerization required for virgin fiber. For example, Repreve recycled polyester reduces greenhouse gas emissions by about 42%, while ECONYL’s regenerated nylon can cut that impact by up to 80%.

- Water and Chemistry: Recycled fibers also use significantly less water and avoid the use of chemicals like adipic acid, which emits nitrous oxide — a potent greenhouse gas.

- Waste and Pollution: Perhaps most importantly, recycling diverts waste from landfills and oceans. Every jacket made from rPET represents dozens of plastic bottles that didn’t become pollution. Every pair of swim shorts made from ECONYL helps keep ghost nets out of the water.

For every 10,000 tons of recycled nylon produced, 57,000 tons of CO₂-equivalent emissions are avoided, and 70,000 barrels of oil are saved. That’s not abstract — that’s tangible climate action, baked into the supply chain.

Of course, recycled synthetics aren’t a silver bullet. They still shed microfibers during washing. Mechanical recycling can only happen so many times before the material degrades. And while the recycling infrastructure for bottles is relatively mature, textile-to-textile recycling is still catching up.

But in a world where virgin synthetics are still the default, recycled content is a meaningful shift. It keeps existing materials in circulation and avoids tapping new fossil resources.

At Foehn, we believe progress comes from iteration — and from thinking long-term. Recycled polyester and nylon are part of that equation. So is supporting innovation in next-gen materials, like bio-based synthetics derived from plants instead of petroleum.