This is the story of ripstop – a special reinforcing weave engineered during World War II to prevent small tears from turning into catastrophic rips. What began as a wartime emergency measure for parachutes has since evolved into a common feature of outdoor gear and apparel, embodying the idea that you can’t always prevent damage, but you can engineer how it fails.

Silk Parachutes

In the early 1940s, parachutes were typically made of silk, a strong yet lightweight fabric imported mostly from Japan. When World War II broke out, that silk supply was cut off – Japan was at war with the U.S., and silk became unobtainable for American use . The U.S. military suddenly needed an alternative material for parachute canopies, and they needed it fast. Enter nylon, a brand-new synthetic fiber invented by DuPont chemists in the mid-1930s . Nylon (specifically the polymer known as nylon 6,6) was first synthesized in 1935 by Wallace Carothers at DuPont, and by 1938–39 it was being touted as a revolutionary artificial fiber. Crucially, nylon had the right properties for parachutes: it was light, very strong for its weight, and could be mass-produced domestically. In fact, its strength, elasticity, light weight, and resistance to mildew made it ideal for military applications .

When the U.S. entered WWII, DuPont swiftly shifted nylon production from consumer goods (like women’s stockings) to military uses. By late 1941, virtually all nylon output was being diverted to making parachutes (as well as cords and ropes), directly replacing Japanese silk . American parachute factories began producing all-nylon parachutes to supply the war effort. Nylon was a godsend material – except the military soon discovered one critical drawback.

Nylon’s Strength

While nylon was strong and light, parachute engineers found it had a tendency to “run” if cut or torn. In a plain woven silk or nylon fabric, a small puncture or rip could rapidly spread along the weave, tearing a large gap. In other words, once a tear started in the cloth, it would continue along the path of least resistance (following the weave yarns), causing the fabric to split further under stress . This property was obviously not ideal when you’re falling from a plane – even a tiny hole in a parachute canopy could suddenly enlarge and lead to catastrophic failure. Reports of rips ruining parachutes (sometimes while in use) alarmed Allied researchers . You can imagine the urgency: paratroopers and pilots needed assurance that their chutes wouldn’t fail due to a minor rip or bullet hole. As one historical account noted, DuPont had marketed nylon stockings as “run-free,” but in reality nylon fabrics could develop runs (elongated tears) . The challenge was clear: if nylon parachutes could not be made completely tear-proof, perhaps they could be engineered to prevent small tears from spreading further.

Inspiration from Sail Cloth

Textile engineers began searching for a solution to nylon’s tearing issue. Interestingly, the basic idea for a fix wasn’t entirely new – it echoed a principle long used in other contexts. For centuries, sailmakers had wrestled with heavy canvas sails that faced high wind loads and rough conditions. A rip in a ship’s sail during a gale could be disastrous, so sailmakers learned to reinforce their canvas and confine tears to a small area. Traditionally this was done by adding extra layers or using heavier yarn in critical sections, effectively creating localized strength so that a failure in one part of the sail wouldn’t slit the whole sheet . The concept was simple: you can’t always prevent a tear, but you can engineer the fabric to fail locally, not catastrophically.

Applying this logic to nylon parachutes, engineers at DuPont and other military research labs developed a special reinforcing weave for the fabric. Instead of a uniform plain weave, they wove the material with a grid of thicker, stronger threads interlaced at regular intervals. In practice, this meant inserting high-denier (high thickness) nylon yarns every few millimeters in both warp and weft directions of the cloth, forming a subtle geometric grid within the fabric . These thicker strands acted like tiny ribs or netting inside the cloth. If the fabric got a puncture or cut, the tear would run into one of these robust grid fibers – and stop. The grid of heavy yarns compartmentalized any rip, preventing it from propagating further across the material . This innovation was soon dubbed “ripstop” because it literally stopped rips in their tracks.

By the mid-1940s, ripstop-weave nylon had been implemented in parachute production. The U.S. Army and parachute manufacturers incorporated the new “rip-stopping” fabric to make tougher canopies . The problem of tearing wasn’t eliminated entirely, but the failure mode was now contained – a life-saving improvement. It’s worth noting that while ripstop fabric was used informally during WWII, the technique wasn’t formally patented until much later. In 1962 a patent titled “Parachute Fabric Containing Stretch and Non-Stretch Type Ripstops” was filed by inventors Louis Weiner and Harold Brandt, reflecting the ripstop concept developed for parachutes .

From Parachutes to Packs

What began with parachutes did not end there. After WWII, the value of ripstop fabric was apparent, and the military continued to use it in other gear. Early on, combat uniforms and field equipment such as tents and tarps were made with ripstop reinforcements for added durability . As the decades went on, the technology spread to civilian applications. By the 1960s and 1970s – an era of rapid growth in outdoor recreation and adventure gear – the outdoor industry eagerly adopted ripstop fabrics . Manufacturers of tents, camping shells, backpacks, and sleeping bags found that ripstop nylon and polyester allowed their products to be both lightweight and resistant to real-world wear and tear. A thin tent wall, for example, could withstand rough weather or an accidental puncture much better if it was made of ripstop material rather than ordinary weave cloth. If a campfire spark burned a tiny hole, the damage would stay localized in one small square of the grid instead of shredding the whole panel.

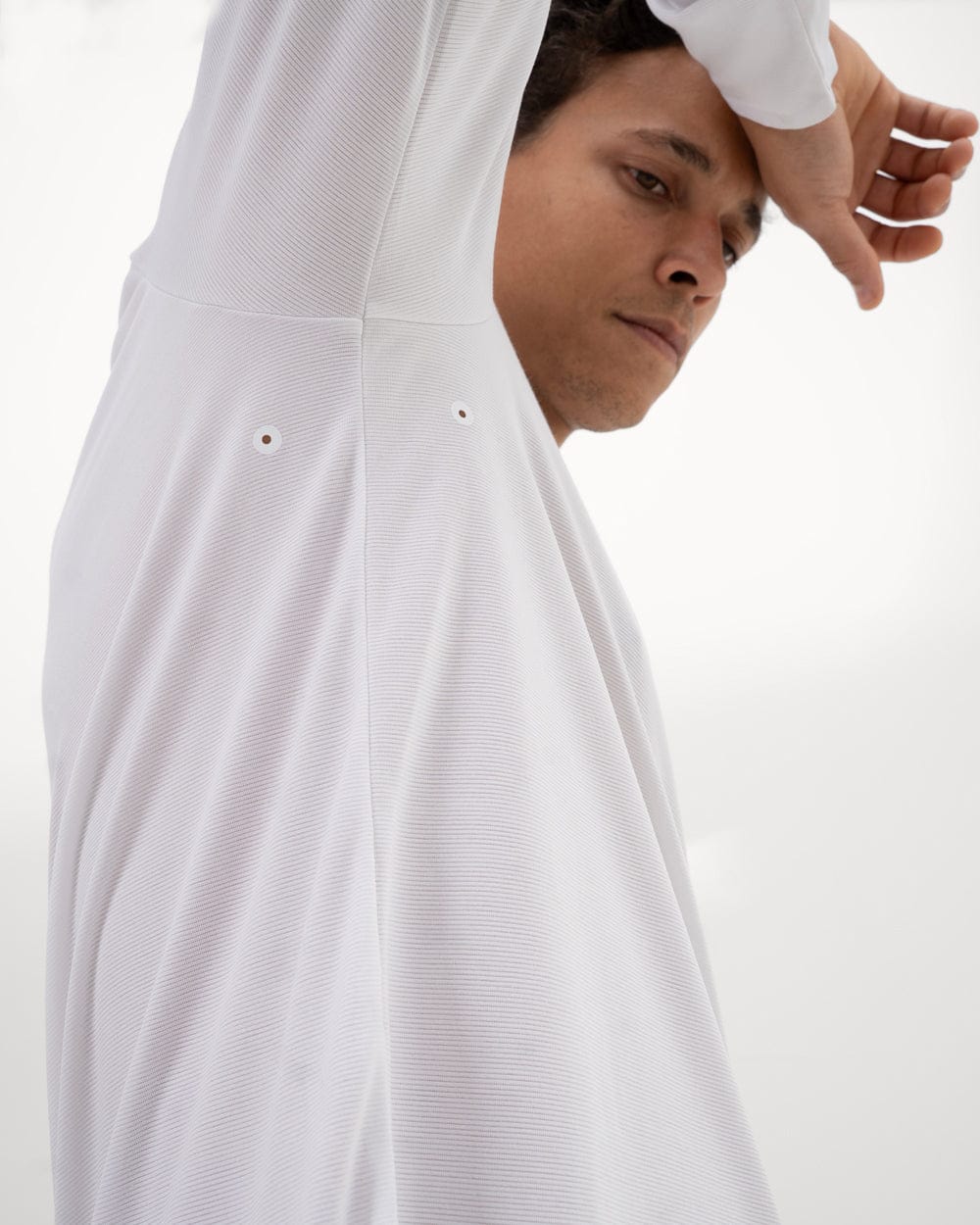

By 1980, ripstop had advanced to the point where even high-wear military clothing (like U.S. Battle Dress Uniforms) were using it for improved tear resistance . From that time onward, ripstop became a standard option for any application demanding a strong yet lightweight fabric. Today, you’ll find ripstop everywhere — even if you don’t notice it. The fabric’s telltale grid pattern is used in an enormous range of products and industries. For example, modern outdoor gear and apparel almost ubiquitously feature ripstop weaves: everything from hiking pants and rain jackets to ultralight tents and kites. Safety and sporting equipment also take advantage of it, including parachutes (still!), paragliders, hot air balloons, sails for boats, hang gliders, and wingsuits . Even everyday items like luggage, flags, and banners often use ripstop to ensure longevity . In fact, some heavy-duty fabrics incorporate ripstop reinforcements into otherwise thick materials (for instance, firefighter uniforms or workwear) to increase durability . Ripstop has become so common that many people wear or use something made of ripstop fabric without realizing it – the grid can be subtle, and modern weaving techniques sometimes make the reinforced threads less obvious .

A Woven Legacy

From the desperate needs of World War II to the high-tech textiles of today, the evolution of ripstop fabric illustrates a profound engineering insight: you can’t always prevent damage, but you can control how damage spreads. The invention of the ripstop weave meant that a soldier’s parachute could survive a small rip and still save his life. That same principle now gives climbers, campers, soldiers, and even astronauts greater confidence in their gear. Ripstop’s little grid pattern is a reminder that sometimes the best solution is not to make something unbreakable, but to design it so that if it does break, it fails safely. In fabrics as in engineering at large, localizing failure can avert total disaster – a legacy woven right into the fabric of the modern world.