Early Outdoor Gear

Early 20th-century skiers relied on heavy wool layers for warmth and weather protection. Wool was the original “performance” fabric – prized for its insulation even when wet and its durability under harsh conditions. Early mountaineers like Balmat and Paccard (who summited Mont Blanc in 1786) layered oversized wool coats, wool stockings, and felted knickers as their primary defense against alpine cold. The fiber’s structure gave wool unique advantages: wool can absorb over 30% of its weight in moisture before feeling damp, yet its natural lanolin oils repel rain on the fiber surface. This means wool garments still insulate when soaked – a lifesaver in cold, wet climates. In fact, wool is hygroscopic: as it adsorbs water vapor, it releases a small amount of heat (a process called “heat of sorption”), which can actually help keep a wearer warm as the wool dries. These qualities made wool the backbone of outdoor apparel well into the mid-20th century, from the thick woolen underwear issued to WWII soldiers to the classic wool plaid shirts and trousers worn by hunters and climbers.

Jacques Balmat illustrated on the first ascent of Mont-Blanc, via WikiCommons

Of course, wool had drawbacks. Wet wool is heavy and can take a long time to fully dry out. Early adventurers in wool often suffered carrying water-laden garments. And while tightly woven wool (like gabardine) is somewhat wind-resistant and was used in early outerwear, wool alone was no match for driving rain without a waterproof layer. By the mid-1900s, the limitations of wool, combined with new material science breakthroughs, set the stage for a revolution in outdoor fabrics. Innovators began seeking materials that could provide similar all-weather comfort with less weight and faster drying times. The answer would come from the realm of synthetic polymers.

The Rise of Synthetics (1940’s-1970’s)

The first major shift in outdoor fabrics came with the invention of nylon by DuPont in the late 1930s. Unveiled at the 1939 World’s Fair as a marvel of modern chemistry, nylon was the world’s first true synthetic fiber. It boasted impressive strength, elasticity, and resistance to mildew or rot – properties that natural fibers like silk or cotton could not match. During World War II, nylon’s durability helped the Allied war effort: it replaced silk in parachutes and was used in ropes, tents, and gear, demonstrating extraordinary toughness for its light weight. (Nylon climbing ropes, for example, could stretch under load and absorb shock, a life-saving improvement over old hemp ropes.) By the 1950s, as consumer production ramped up, nylon began appearing in civilian outdoor apparel.

Around the same time, scientists in Britain developed polyester (first branded as Terylene in 1941). Polyester shares nylon’s advantages of being hydrophobic (repelling water) and quick-drying, though it’s generally weaker than nylon. In the 1960s, outdoor companies started blending synthetics into their designs. A famous example was the 60/40 cloth anorak introduced by Sierra Designs in 1968, which blended 60% cotton with 40% nylon – the cotton swelled when wet to block water, while the nylon added strength and reduced weight. This was an early “technical fabric” for shell jackets, offering better breathability than full rubber rain slickers and better rain resistance than all-cotton canvas. By the late 1960s, lightweight nylon parkas and shell pants were increasingly common on serious climbs, helping climbers stay dry and agile in volatile weather.

Polar Fleece ad prior to Malden Mills changing their name to Polartec

The true synthetic revolution in insulation fully arrived in the 1970s with the invention of polar fleece. In 1979, Massachusetts-based textile mill Malden Mills (later known as Polartec) partnered with Yvon Chouinard of Patagonia to create a plush polyester pile fabric that mimicked wool’s warmth but at a fraction of the weight. The resulting synthetic fleece debuted in 1981, offering campers and mountaineers a game-changing midlayer that was soft, warm, fast-drying, and light. Unlike old wool sweaters, the fluffy fleece didn’t absorb much water at all – it could wick perspiration and allow it to evaporate, keeping the wearer drier. Its warmth-to-weight ratio surpassed that of wool, and it retained loft after repeated compressions. By the mid-1980s, fleece jackets were ubiquitous in the outdoors, often worn in eye-catching bright colors that the dyeable polyester made possible.

Another synthetic fiber that changed outdoor apparel was polypropylene. Introduced in the 1970s, “polypro” made excellent base layer garments because it was even more hydrophobic than polyester – it literally would not absorb water. Brands like Helly Hansen launched polypropylene thermal underwear (e.g. Lifa®) that became popular with skiers and sailors for pulling sweat off the skin. The stage was set: by the end of the 1970s, outdoor enthusiasts could wear a full synthetic ensemble – polypro base T-shirt, a polyester fleece jacket, and a nylon wind shell – achieving comfort across a range of conditions that old wool and canvas gear struggled to match. But one problem remained unsolved: how to stay dry not just from sweat, but from rain, without trapping sweat in the process. The answer arrived in the form of a deceptively thin plastic membrane – and it revolutionized outdoor gear forever.

Gore-Tex (1970’s)

In 1969, chemist Robert “Bob” Gore made a discovery that would utterly transform rainwear. By rapidly stretching a heated rod of PTFE (Teflon), he created a microporous film of expanded PTFE (ePTFE) – a material that could stop liquid water but allow water vapor to pass through. This ePTFE membrane became the heart of Gore-Tex, the world’s first waterproof breathable fabric, patented in 1976. Traditional rain gear before Gore-Tex was non-breathable (rubber, PVC, or coated nylon) – it kept rain out but also trapped sweat in, often leaving the wearer soaked from inside. Gore-Tex promised something revolutionary: stay dry from rain and perspiration at the same time.

The Gore-Tex membrane contains about 9 billion pores per square inch, each pore roughly 1/20,000 the size of a water droplet. Rain drops are far too large to penetrate these tiny holes, but water vapor molecules from sweat are much smaller and can slip out. Backing and face fabrics are laminated to the delicate membrane to create usable textiles for jackets, tents, and boots. The result is gear that is windproof and waterproof on the outside, yet allows humidity to diffuse outward, greatly reducing the dreaded “trash bag effect” of old raincoats. The material quickly achieved household name status in outdoor circles.

Schoeller Textil AG

High-Performance Fabrics (1990’s)

In the 1990s and early 2000s, material innovation in outdoor gear accelerated, focusing on moisture management, thermal efficiency, and stretch/compression – often referred to as the layering system revolution. Having introduced fleece to great success, Polartec (Malden Mills) spent the ’90s developing a whole family of technical fabrics to fine-tune each layer of clothing. One milestone was Polartec Power Dry, launched in 1994 as one of the first purpose-built next-to-skin fabrics. Power Dry used a bi-component knit: a hydrophilic inner face that pulled sweat off the skin, and a hydrophobic outer face that spread moisture out to dry quickly.

Meanwhile, in Switzerland, Schoeller Textil AG was innovating high-performance fabrics of its own. Schoeller had actually produced stretchy “soft-shell” ski pants as early as 1961, but in the 1990s they introduced Schoeller® Dryskin Extreme, a double-weave nylon with a tough outer surface and a soft, warm inner face. Dryskin became legendary for softshell pants and jackets used by mountaineers: it was water-repellent and wind-resistant enough for most weather, extremely abrasion-resistant against rock, and had comfortable stretch.

The result of these technical innovations was a layering system that was lighter, less bulky, and more breathable than the old 1970s combination of wool shirt, heavy sweater, and non-breathable raincoat. Each piece was optimized for a specific role in managing moisture, airflow, and insulation. This period truly perfected the art of comfort in outdoor clothing.

Modern Innovations

One of the most significant shifts in outdoor fabric technology today is the industry-wide move away from PFAS (per- and polyfluoroalkyl substances). Long used in waterproof membranes and DWR coatings, PFAS are now being phased out due to health and environmental concerns. Brands are exploring new waterproof membranes made of expanded polyethylene (ePE), polyurethane (PU), and other fluorine-free options. These materials aim to retain the waterproof-breathable performance of traditional membranes without the persistence or toxicity of PFAS. By 2025, many major brands are expected to offer PFAS-free outerwear.

Graphene, a one-atom-thick carbon lattice, is another emerging innovation. Known for its exceptional strength and thermal conductivity, it's being explored in jackets and linings to help regulate heat, resist odor, and add durability. Though still experimental, graphene hints at a future of smart, performance-enhancing fabrics.

Another standout material is Dyneema®, often called the world’s strongest fiber. Originally developed for industrial and military use, Dyneema is now used in ultralight backpacks, shelters, and apparel where strength-to-weight is critical. It’s up to 15 times stronger than steel by weight and highly resistant to abrasion, moisture, and UV damage. While expensive, Dyneema's use in outdoor gear has grown steadily among fast-and-light alpinists and thru-hikers who need maximum durability with minimal bulk.

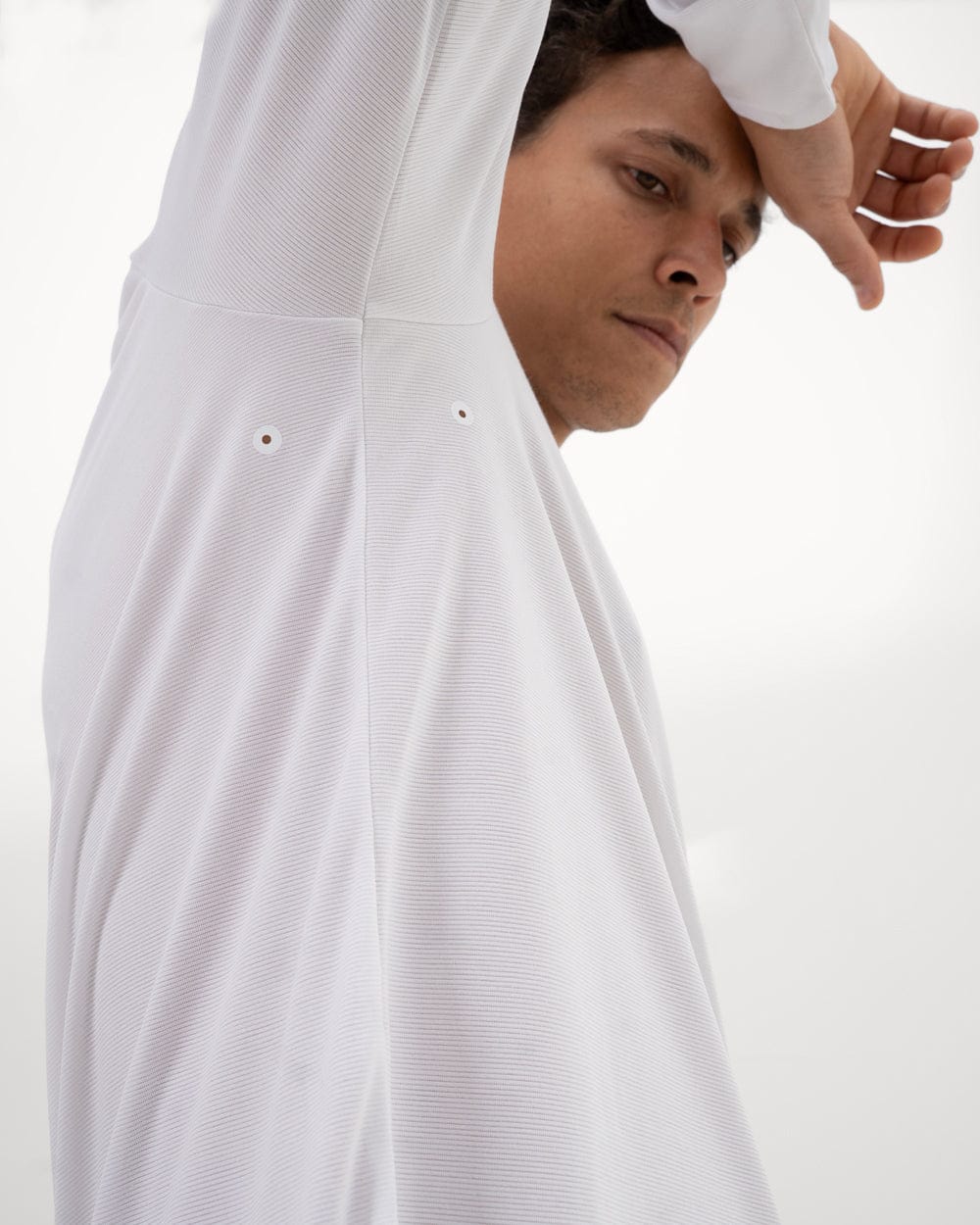

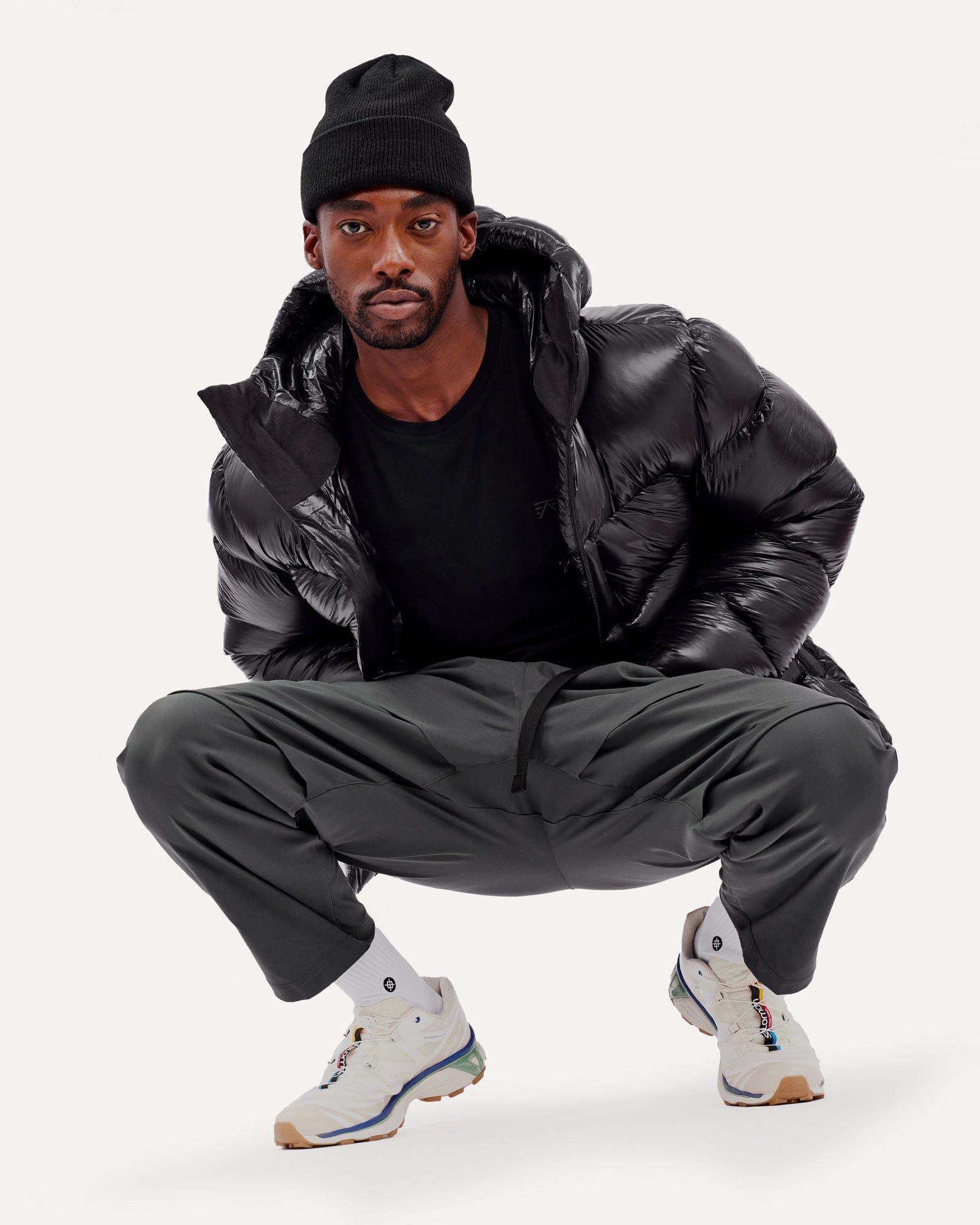

Salem Dyneema Down Parka By Foehn, circa 2022

In Conclusion

From wool to synthetics, and now toward sustainable and bio-based materials, outdoor fabrics have evolved through decades of innovation. The first priority was function: staying dry, warm, and mobile. But as performance has reached new heights, the focus is shifting toward environmental responsibility.