When we think of sustainable synthetics, recycling often takes the spotlight. But there’s another powerful path forward: bio-based polymers— fibers made from renewable biological resources instead of fossil fuels. Swiss textile pioneer Schoeller® is leading this shift, using bio-based polyester to reduce dependence on oil without compromising performance.

At its core, it’s still polyester — strong, versatile, and durable — but made partly from plants instead of petroleum. Traditional polyester is created from chemical building blocks sourced entirely from oil. In a bio-based version, one of those key ingredients — ethylene glycol— is swapped for a plant-derived alternative, often made from corn or sugarcane. The second ingredient, terephthalic acid, is typically still fossil-based (for now). The result? A material with identical technical performance but a smaller environmental footprint.Schoeller’s version falls into this category. According to industry sources, it contains 37% bio-based content— likely referencing the use of DuPont’s Sorona® PTT, a partially bio-based polyester made with Bio-PDO™, a 1,3-propanediol derived from corn glucose.

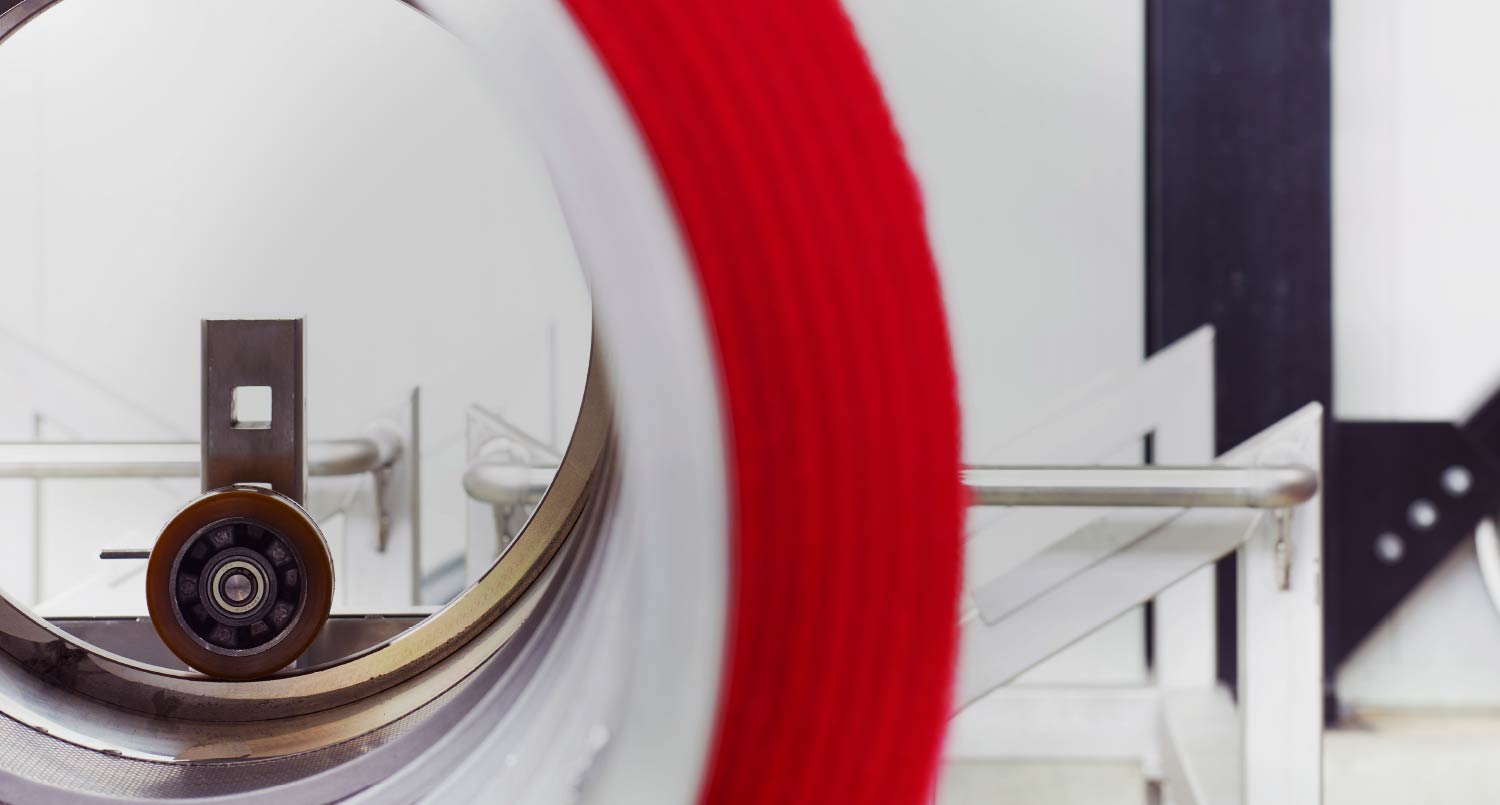

Here’s how the process works: corn sugar is fermented to produce Bio-PDO™, which is then combined with terephthalic acid to create polytrimethylene terephthalate (PTT) — the backbone of Sorona®. Schoeller integrates this polymer into select technical fabrics, delivering inherent stretch, softness, and resilience, while lowering fossil resource use.

Switching to bio-based inputs helps reduce reliance on petroleum and can significantly lower a material’s carbon footprint. Since the carbon in plants comes from the atmosphere, this creates a partially closed-loop carbon cycle — unlike fossil-based materials, which introduce new carbon into the system. Life-cycle analyses show that partially bio-based PET can cut greenhouse gasemissions by ~20%, and fully bio-based versions offer even greater reductions.

Bio-based materials also expand and diversify the raw material supply chain. Instead of everything flowing from oil refineries, some fibers now begin on farms. (With caveats: responsible sourcing is critical to avoid competition with food or harmful land-use impacts. In Schoeller’s case, the corn sugar used is often a byproduct of other agricultural processes.)

Even more compelling is the possibility for end-of-life innovation. Schoeller’s biophilic polyesteris designed to biodegrade in various environmental conditions— a game-changing advance that could drastically reduce microplastic pollution if these fibers end up in waterways or soil. A synthetic that performs like polyester, is made in part from plants, and breaks down at the end of its life? That’s a serious evolution.

Interestingly, the logic behind bio-based inputs mirrors that of pre-consumer recycling— both tackle sustainability at the raw material stage. Instead of relying solely on post-consumer waste, they aim to reduce impact by rethinking where materials come from in the first place. Whether it’s transforming plant sugars into polymers or capturing factory-floor scrap before it’s ever used, both approaches reduce the need for virgin fossil-based resources. They’re upstream interventions — ways to lower the environmental cost before a product is even made.

While recycled polyester addresses the output side of the equation — reusing plastic waste — bio-based tackles the input: where raw materials come from. Both approaches are crucial. And because bio-based polyesters are chemically identical to conventional PET, they can enter the same recycling streams, keeping the loop intact.

The ideal future isn’t either-or —it’s both. A jacket made from plant-based inputs that can be recycled again and again. Or one that biodegrades safely when its time is up.

Schoeller’s work reflects a broader movement in material science. Toray’s Ecodear® uses 30% plant-based content. Companies like Covestro are experimenting with CO₂-based feedstocks. New bio-polyesters are hitting the market every year. The long-term vision is clear: high-performance materials that are net-zero carbon, made from waste or atmospheric CO₂, and engineered to safely decompose or cycle endlessly.

Schoeller’s bio-based polyester is a meaningful step in that direction. It proves that synthetics don’t have to be at odds with sustainability. Through thoughtful innovation, we can reimagine what technical apparel is made of — and how it fits into the planet’s future.