In the outdoor industry, most innovations arrive slowly. A new fabric is introduced, refined over time, and eventually filters into mainstream products. But occasionally, a technology comes along that redefines how entire categories of gear are designed. That was the case with Polartec Alpha.

Released commercially in 2013, Alpha was unlike anything on the market. It wasn’t a new version of down, or a slightly better fleece. It was a complete rethink of how insulation could perform — not just during rest, but in motion. For athletes, soldiers, and anyone who moved through the cold at pace, it quietly solved a problem that had long been accepted as unsolvable: how to stay warm and dry while active.

But Alpha didn’t start in the outdoor world. Its origins trace back to the U.S. military — and a very specific challenge.

A Mission-Critical Problem

In the early 2010s, the U.S. Special Operations Forces were operating in cold, mountainous regions like Afghanistan, where conditions changed rapidly and movement was constant. The existing cold-weather clothing systems were layered — base, fleece, synthetic fill, shell — and while they worked in theory, they struggled in reality. Soldiers were either overheating while moving or freezing when stationary. Sweaty baselayers became soaked, then dangerously cold during rest. Stopping to strip layers or vent garments was impractical, if not outright dangerous.

The military’s textile brief was clear: create a new form of insulation that could retain warmth while allowing sweat and moisture to escape quickly. The goal wasn’t just to insulate better. It was to insulate intelligently. The insulation needed to regulate temperature, dry fast, resist compression, and hold up to hard use — all while reducing the need for constant layering changes in the field.

Polartec, with its long history of innovation (including inventing synthetic fleece), took on the challenge. The result was Alpha — and it marked a radical departure from how insulation had traditionally been built.

Developed for U.S. Special Forces to perform in motion, not just in the cold.

Alpha’s Construction

Most synthetic insulations at the time were designed as batting. That meant thin sheets of loosely organized polyester fibers — similar to down in performance and use — sandwiched between an inner liner and outer shell. These insulations worked well in static situations, but they had three limitations: they trapped heat too aggressively during movement, retained moisture, and required barrier fabrics to hold the insulation in place. That barrier prevented airflow and slowed drying.

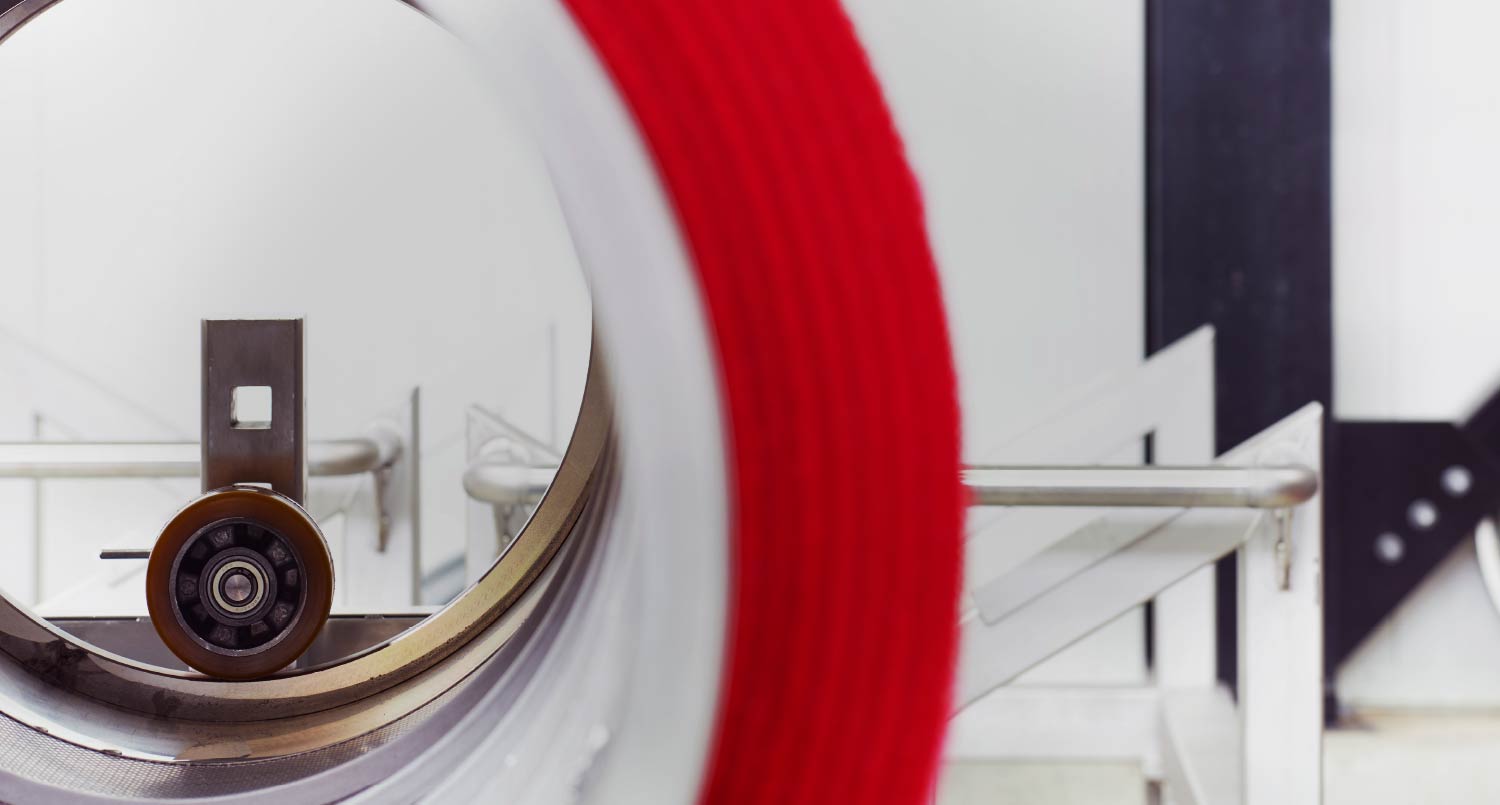

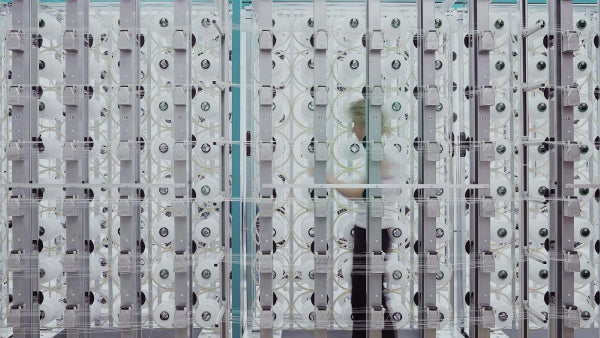

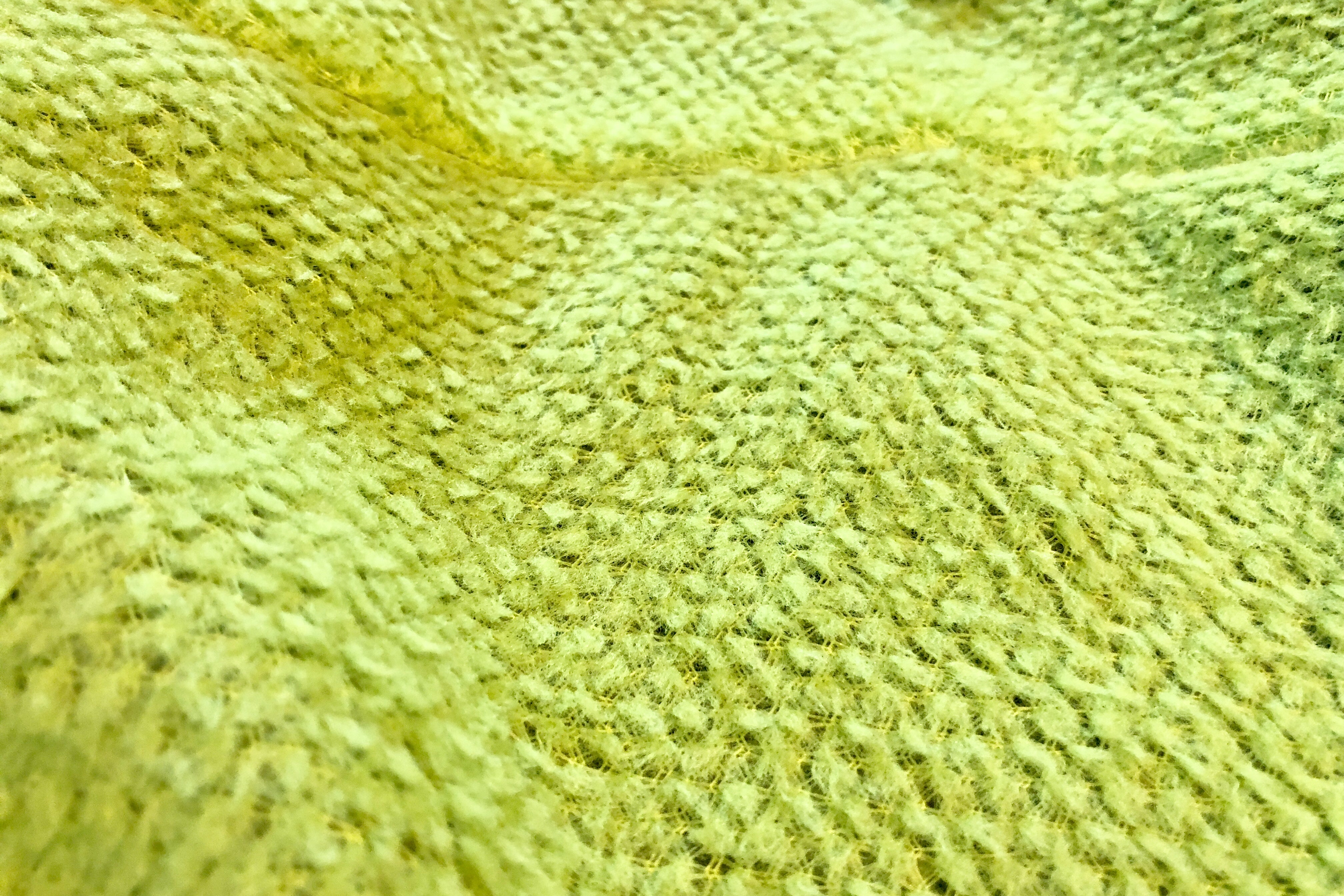

Polartec Alpha broke with that model. Instead of loose fill, Alpha was engineered as a knit structure — a continuous, stable network of crimped polyester fibers anchored to a mesh base. The fibers were arranged in a way that allowed real loft (essential for trapping air and retaining warmth), but the knit remained open enough to allow high levels of air permeability. This made Alpha perform more like a fabric than a fill.

The benefits were immediate and measurable. Because of its open structure, Alpha allowed excess body heat and vapor to escape before they could condense into sweat. The hydrophobic nature of the polyester fibers meant that it absorbed very little moisture to begin with — and what little it did absorb dried quickly. The stable loft avoided clumping or migration, so there was no need for quilting or baffles. Designers could use Alpha in new ways, simplifying construction and reducing bulk.

This wasn’t an incremental update. It was a material solution that enabled a whole new philosophy of performance layering.

A continuous, stable network of crimped polyester fibers anchored to a mesh base.

What “Active Insulation” Means

The term “active insulation” has become a marketing buzzword, but Polartec Alpha was the original — and arguably still the best — execution of the concept. It was designed to function while the wearer was moving. That sounds simple, but it fundamentally changes the insulation brief. Most insulations are built for rest: parkas for camp, puffies for the lift line, fleece for après. Alpha, by contrast, was built for effort — hiking with a pack, ski touring uphill, running in shoulder seasons, climbing in fluctuating weather.

The defining characteristic of Alpha was its thermal adaptability. It kept the body warm enough when static, but unlike down or traditional fleece, it didn’t overheat during movement. The lofted knit allowed internal microclimates to adjust in real time. Warm air could escape through the gaps between fibers; moisture could evaporate directly through the insulation layer. The result was a stable thermal environment — one that responded to effort and climate, instead of ignoring it.

This dynamic performance made Alpha particularly well-suited to cold-and-wet environments, where the goal isn’t maximum warmth but moisture management. In many ways, Alpha shifted the insulation conversation away from absolute R-values and toward comfort in real-world use.

The Outdoor Industry

When Polartec Alpha became available to outdoor brands in 2013, it entered a market still entrenched in traditional layering systems. Early experiments with Alpha, integrated it into garments in the conventional way — encasing it between a face fabric and a liner, treating it like synthetic fill.

While those pieces were still highly breathable compared to traditional insulation, they didn’t fully unlock Alpha’s potential. The inner and outer fabrics — often tightly woven for wind or abrasion resistance — reduced air permeability, limiting Alpha’s ability to self-regulate. Moisture could still accumulate. Drying times improved, but not dramatically. The result was a better-performing midlayer — but not the revolutionary garment Alpha could enable.

Part of the problem was aesthetic. The raw surface of Alpha wasn’t designed to be seen. It looked like a fuzzy mesh — lightweight, high-tech, and effective, but unfamiliar. Designers needed time (and better materials) to build garments that could showcase Alpha’s performance without compromising durability or fit.

That breakthrough came in 2017, when Polartec released Alpha Direct.

Alpha Direct

Alpha Direct was an evolution of the original concept — a more refined, abrasion-tolerant version of Alpha that no longer needed a backing fabric. With Alpha Direct, designers could eliminate the inner lining entirely. The insulation itself became the inside of the garment.

This had two key effects. First, it vastly increased breathability and moisture vapor transport. With no liner to slow airflow, sweat could escape directly from the baselayer through the insulation and out through the shell — or through open panels, if no shell was used. Second, it simplified construction. Fewer layers meant lighter garments, faster drying times, and fewer failure points.

Alpha Direct also opened the door to new design strategies. Because the insulation didn’t migrate or collapse, it could be used in hybrid garments — exposed in some areas, covered in others. Many brands began combining Alpha Direct with other Polartec technologies, like Power Grid or Power Stretch, to create fine-tuned layering systems optimized for specific activities.

This was the moment when Alpha moved from “better synthetic insulation” to material platform — something designers could shape, customize, and integrate into complex garment systems for dynamic use.

Senchi Designs Alpha 120 Hoodie with pocket

The Legacy of Alpha

The introduction of Alpha Direct marked a quiet but fundamental shift in how cold-weather layering was approached. For decades, performance layering relied on a choreography of adding and removing garments — a fleece for the climb, a shell for wind, a puffy for rest. These systems worked, but they were reactive. Managing moisture and temperature meant constantly adapting, often interrupting the rhythm of movement. Alpha Direct enabled something different: garments that could stay on across a range of conditions, reducing the need to shed or swap layers. Breathable enough for effort, insulative enough for pause, fast-drying enough to recover between transitions — Alpha created a stable thermal environment that responded to the body in motion. It simplified layering decisions, lightened packs, and made gear feel more intuitive. The result was not just a new insulation material, but a new way of thinking about how we dress for the cold.

More than a decade after its introduction, Alpha’s impact is still unfolding. It didn’t aim to replace down, fleece, or traditional synthetics — it aimed to solve a different problem: how to keep moving without overheating, and how to stay warm without getting wet. In doing so, Alpha helped redefine what performance insulation could be. It shifted the focus away from maximum warmth and toward dynamic regulation. It reminded designers and users alike that comfort isn’t just about heat — it’s about control, balance, and breathability. Alpha didn’t just change insulation. It changed expectations. And it reshaped how we design for motion in the mountains.