Outdoor apparel is entering a new era where performance must align with sustainability. Waterproof-breathable jackets, once synonymous with Gore-Tex, are being reexamined under the lens of PFAS (“forever chemical”) bans, microplastic pollution, and green innovation.

But first, a baseline: what are PFAS, and why do they matter so much?

What Are PFAS?

PFAS stands for Per- and Polyfluoroalkyl Substances, a large family of synthetic chemicals used since the 1940s in everything from non-stick cookware and food wrappers to stain-resistant carpets and waterproof gear. Their popularity stems from the fact that they are incredibly resistant to heat, water, oil, and chemical degradation.

The catch? PFAS are also known as “forever chemicals” because they don’t break down in the environment or the human body. They accumulate over time — in soil, waterways, wildlife, and people — and have been linked to a range of serious health concerns including hormone disruption, immune suppression, and certain cancers. There are thousands of types of PFAS, but they all share a common bond: the carbon-fluorine link, which is among the strongest in chemistry. This is what makes PFAS-based materials both effective and environmentally persistent.

In outdoor gear, PFAS appear in two main areas: ePTFE membranes, which are waterproof-breathable barriers often found in jackets and footwear (like Gore-Tex) & Durable Water Repellent (DWR) coatings, which are surface finishes applied to fabrics to make water bead off. But the question remains, is it possible to stay dry outdoors without leaving behind a trail of toxic chemicals?

ePTFE Membranes

What is ePTFE? Expanded polytetrafluoroethylene (ePTFE) is a stretched form of PTFE (the same Teflon polymer used in non-stick pans) that creates a microporous membrane. Bob Gore discovered ePTFE in 1969 by rapidly stretching PTFE, producing a strong, porous film. Each square inch of an ePTFE membrane contains about 9 billion microscopic pores, roughly 20,000 times smaller than a water droplet (yet ~700 times larger than a water vapor molecule) This pore size difference is the magic behind Gore-Tex: liquid rain can’t penetrate, while sweat vapor can escape, making the fabric waterproof and breathable. The membrane itself is extremely thin (about 0.01 mm) and is typically sandwiched between a protective lining and an outer textile for durability.

How it functions in gear: In a classic 3-layer Gore-Tex jacket, the ePTFE membrane is laminated to a face fabric (usually nylon) on one side and a backer fabric on the other. The hydrophobic PTFE pores repel water but allow moisture vapor through, keeping rain out while letting perspiration evaporate. The result is gear that keeps you dry from outside rain and from inside sweat. This principle is common to many waterproof-breathable products.

PFAS connection: PTFE is a fluorinated polymer, meaning it falls under the broad class of PFAS (thus PTFE = PFAS). It’s often called a “forever chemical” because it’s extremely stable and does not biodegrade. Traditional waterproof breathable membranes are made with PFAS — the ePTFE itself is a PFAS-based material (In fact, Gore-Tex production historically involved PFOA, a now-phased-out PFAS processing aid as it is linked to cancer, liver damage, thyroid disease, reproductive issues, and immune system effects.) Virtually every major outdoor apparel company have sold products using ePTFE membranes via Gore-Tex licenses or similar technologies. These membranes have long been the gold standard for all-weather performance, but their PFAS nature means they persist indefinitely in landfills or the environment.

Chemist and entrepreneur Robert W. Gore pulling polytetrafluoroethylene (PTFE). The image is a screenshot from theScientists You Must Know video, in which he discusses his work. Photo Via WikiCommons.

Does ePTFE shed microplastics? Because ePTFE is a type of plastic, any physical wear abrades the membrane and releases tiny PTFE particles (essentially microplastics). However, the membrane is typically hidden and protected inside a jacket, so day-to-day shedding is minimal. Still, washing waterproof gear can release microfibers from the fabric layers – on the order of 1,200 to 9,000 fibers per wash for PTFE-based outdoor gear. Some of these fibers could be fragments of the fluoropolymer membrane or the fabric it’s laminated to. Once shed, PTFE particles will persist for centuries; a PTFE membrane in a landfill may take over 4,000 years to break down, eventually fragmenting into microplastics. In short, ePTFE itself doesn’t biodegrade, and any bits that do slough off become part of the microplastic pollution problem for thousands of years.

Microplastics in the environment: Microfibers from apparel are now found everywhere – from the summit of Mount Everest to the deepest ocean trenches. These fibers are so prevalent that they contribute to the “dust” we breathe and the particles that marine creatures ingest. Over time, persistent polymers like PTFE, polyester, and nylon fragment into smaller and smaller pieces, but never truly disappear. Studies show PTFE microplastics resist UV and biological degradation for centuries, meaning any bits of ePTFE that enter the environment will linger essentially indefinitely.

Human health concerns: Alarming research in recent years has detected microplastics inside the human body. Scientists have found microscopic plastic fibers and fragments in human lung tissue and even embedded in placenta tissue. In 2022, a study reported microplastics in the bloodstream of 80% of people tested, demonstrating that particles we inhale or ingest can circulate and potentially lodge in organs. The health implications of this are not fully understood yet – we’re essentially living through an unintended exposure experiment. However, lab studies give cause for concern: microplastics have been shown to damage human cells in vitro and can carry toxic additives or pollutants on their surfaces. They can also trigger inflammation; imagine your immune system reacting to tiny plastic specks that it cannot break down. Some evidence suggests links to oxidative stress or hormone disruption. It’s clear that we don’t want these particles in our lungs, blood, or placenta, especially since once they’re there, they may accumulate over a lifetime.

Sacramento, View of California State Capitol from 10th Street

California’s PFAS Ban (AB 1817)

Legislation is now catching up with the science, and California’s Assembly Bill 1817 (AB 1817) is a prime example. This law, signed in 2022, prohibits the manufacture or sale of new textile articles containing regulated PFAS in California starting January 1, 2025 “Textile articles” is defined broadly – it includes clothing, outdoor apparel, footwear, accessories, handbags, bedding, towels, and more (basically any consumer goods made of fabric) For the outdoor industry, this is a game-changer because it targets both PFAS-based DWR finishes and PFAS-based membranes like ePTFE.

AB 1817 essentially forces the outdoor apparel industry to eliminate PFAS chemicals on an aggressive timeline. This means rapid innovation or substitution: jackets that previously relied on ePTFE membranes and C6 DWR must be redesigned with PFAS-free membranes (or coatings like PU) and fluorine-free DWR.

PFAS-Free Innovations

Facing these regulatory and environmental pressures, the outdoor industry has been rapidly innovating to develop PFAS-free membranes and coatings that don’t sacrifice performance.

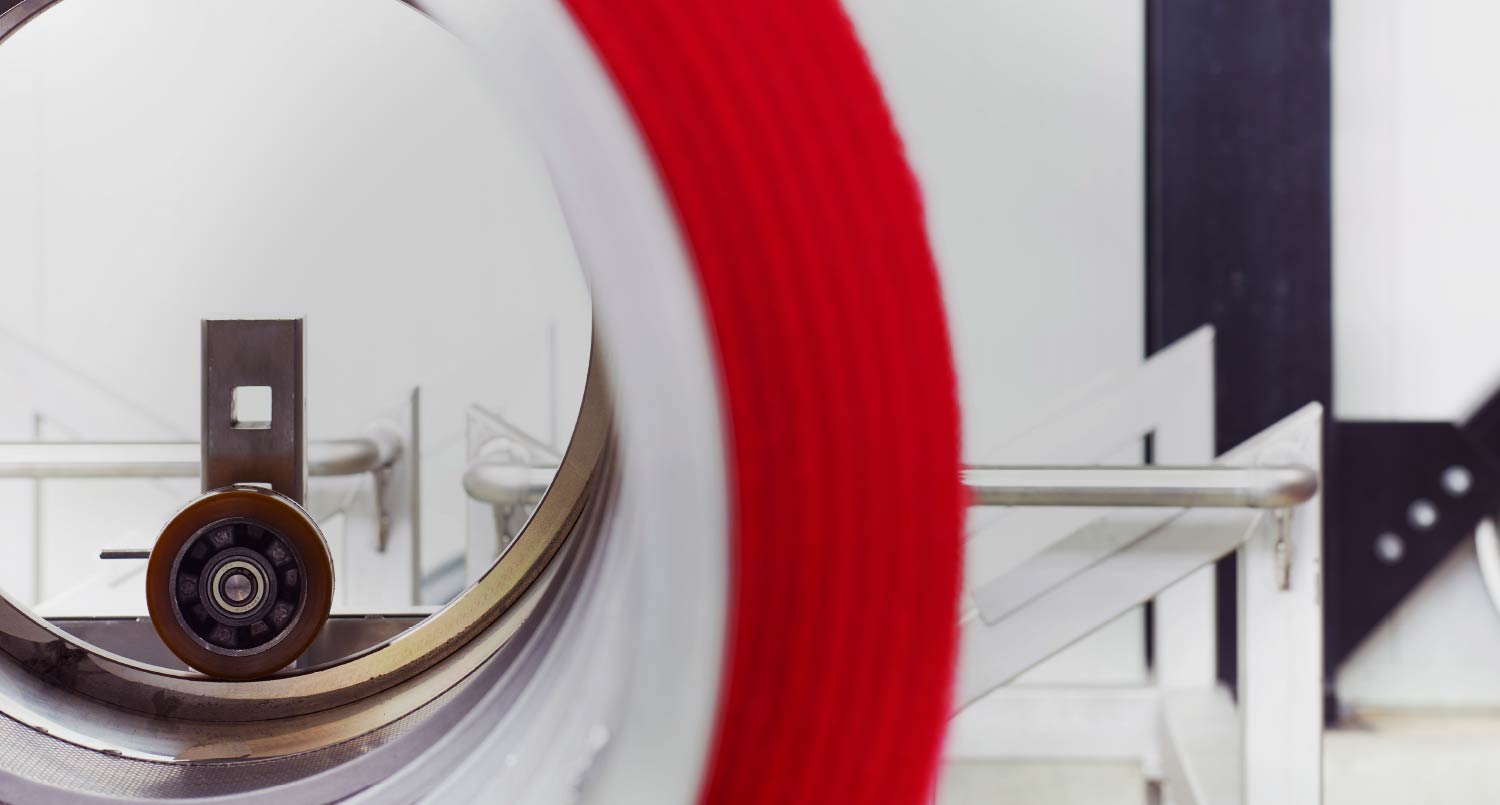

Gore-Tex ePE (expanded Polyethylene) Membrane: This is perhaps the most significant recent innovation. In 2022, W. L. Gore & Associates (maker of Gore-Tex) introduced a new membrane material called ePE, designed to deliver performance without using PTFE. Polyethylene (PE) is a simple, non-fluorinated polymer. By expanding PE with a similar process used for ePTFE, Gore created a microporous PE film – essentially billions of tiny holes that let vapor through but block water, just like ePTFE. To ensure waterproofness, they reinforce the ePE structure with a thin polyurethane (PU) coating, since PE alone is porous; this hybrid construction yields a membrane that is waterproof, windproof, and breathable at about half the thickness of the original Gore-Tex membrane. The ePE production is a non-fluorinated process, which cuts the chemical impact compared to ePTFE manufacturing. Importantly, ePE is completely PFAS-free – it contains no fluorine.

PU and other non-PTFE membranes: Even before ePE, many brands had been using polyurethane (PU) membranes or coatings as PFAS-free alternatives to PTFE. PU is a versatile polymer that can form waterproof films. Traditional PU coatings (found in many low-cost rain jackets) are non-porous – they keep water out but also block airflow, so they rely on slow diffusion of moisture (think of a rubber raincoat, but more breathable than rubber). Newer PU membranes can be made microporous or designed in multi-layer structures to improve breathability. These have no PFAS in the membrane itself. PU membranes historically suffered a bit in durability (hydrolysis over time) and weren’t as consistently breathable under high exertion (since many are monolithic when dry and only transmit moisture when pushed by humidity gradients).

Electrospun Nanofiber Membranes: One exciting category is electrospun membranes, where ultrafine fibers are spun in a random mat, creating a microporous mesh. This can be done with PU or other polymers, and yields air permeability (meaning not just vapor, but even some air can pass, enhancing breathability). These approaches are PFAS-free (no PTFE). Users often report these jackets feel less clammy due to a bit of air exchange. The challenge can be maintaining waterproofness long-term and matching the extreme durability of ePTFE – but they’re improving steadily and are already in use for alpine-grade shells.

Designing for Performance and Planet

The evolution of waterproof-breathable gear is a case study in balancing extreme technical demands with environmental responsibility. ePTFE membranes like Gore-Tex transformed outdoor apparel with their ingenious pore structure, yet came with a hidden environmental cost. Now, driven by legislation like California’s AB 1817 and increasing consumer awareness, the outdoor industry is reinventing its material toolkit. The emergence of PFAS-free membranes (Gore’s ePE, electrospun PU, Sympatex, and others) and improved fluorine-free DWR coatings shows that innovation can align with ecology.

As we wear the next generation of shells and shoes, we’ll not only be shielded from the elements – we’ll also be participating in a broader shift to protect the environment that those elements come from. In the long run, truly durable water repellency will be measured not just in how long a jacket lasts, but in how little impact it leaves over its lifetime. The transition away from PFAS and toward sustainable materials is far from just a regulatory checkbox; it’s part of re-imagining outdoor product design with a conscience.