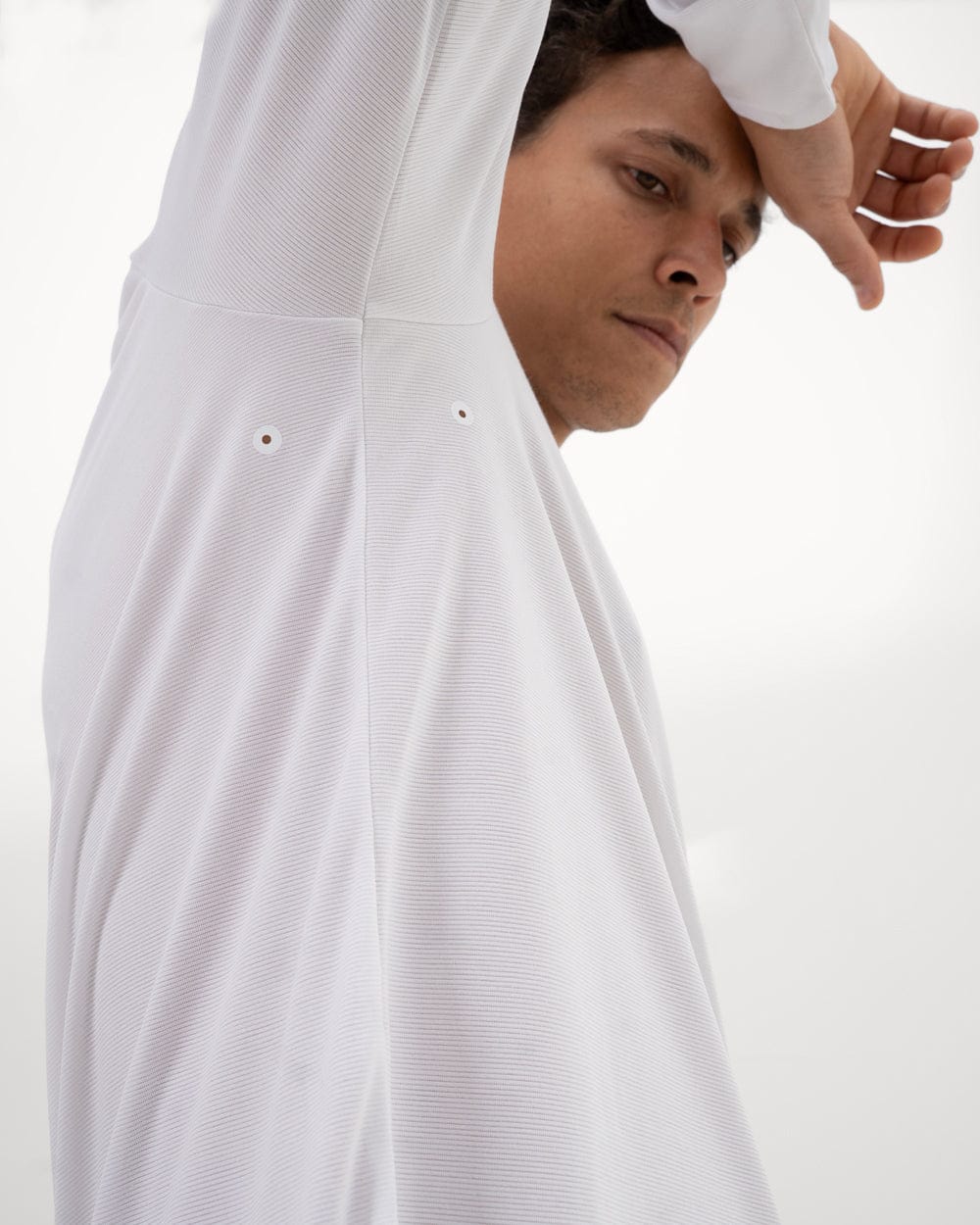

Merino wool - an engineered natural fiber, perfected by evolution and refined by human craftsmanship. It’s the reason your shirt keeps you warm when it’s cold, cool when it’s hot, and odor-free. The journey from sheep to shirt is a five-stage transformation, where every step matters. Let’s take a deep dive into how our Merino wool is processed. Each stage plays a critical role in preserving the softness, strength, and performance characteristics.

From "Brett's Colonists' Guide", (1883) a handbook of useful knowledge for European settlers in New Zealand.

Merino sheep (Ovis aries merino), originally from Spain but now primarily raised in Australia, New Zealand, and South America. These sheep are bred specifically for their ultrafine, soft, dense wool, unlike standard sheep breeds that produce coarser fibers for general-purpose wool. Their finer wool fibers make them significantly softer than standard wool. Primarily raised in cool, mountainous, or arid regions where their fleece helps them adapt to extreme conditions where temperature swings are extreme —hot in summer, freezing in winter. Their wool has naturally evolved to adapt to these fluctuations, making it an ideal temperature-regulating fiber for humans as well. The altitude, climate, and diet of Merino sheep directly influence wool quality—cooler, harsher environments tend to produce denser, finer fleece.

Merino wool undergoes a multi-step transformation from the sheep’s fleece to a finished textile. Each step is crucial to preserve the fiber’s quality and prepare it for knitting:

Photo: Tudor Washington Collins (1898–1970) via Auckland Museum.

Shearing is the first step in merino wool processing and is done once per year, typically inspringwhen the sheep naturally shed their thick winter coats. A skilled shearer can remove the entire fleece in under two minutes, in a single, continuous piece to preserve fiber integrity, which is essential for proper classing and grading. Once the fleece is removed, it’s immediately inspected and classified by experienced wool graders. They evaluate several key quality factors: micron count (which determines softness), staple length (which affects yarn strength), crimp (for elasticity), color purity, and the presence of vegetable matter like burrs or grass. Only the top-grade, ultrafine Merino is separated from coarser wool and sent forward for processing into high-performance fabric.

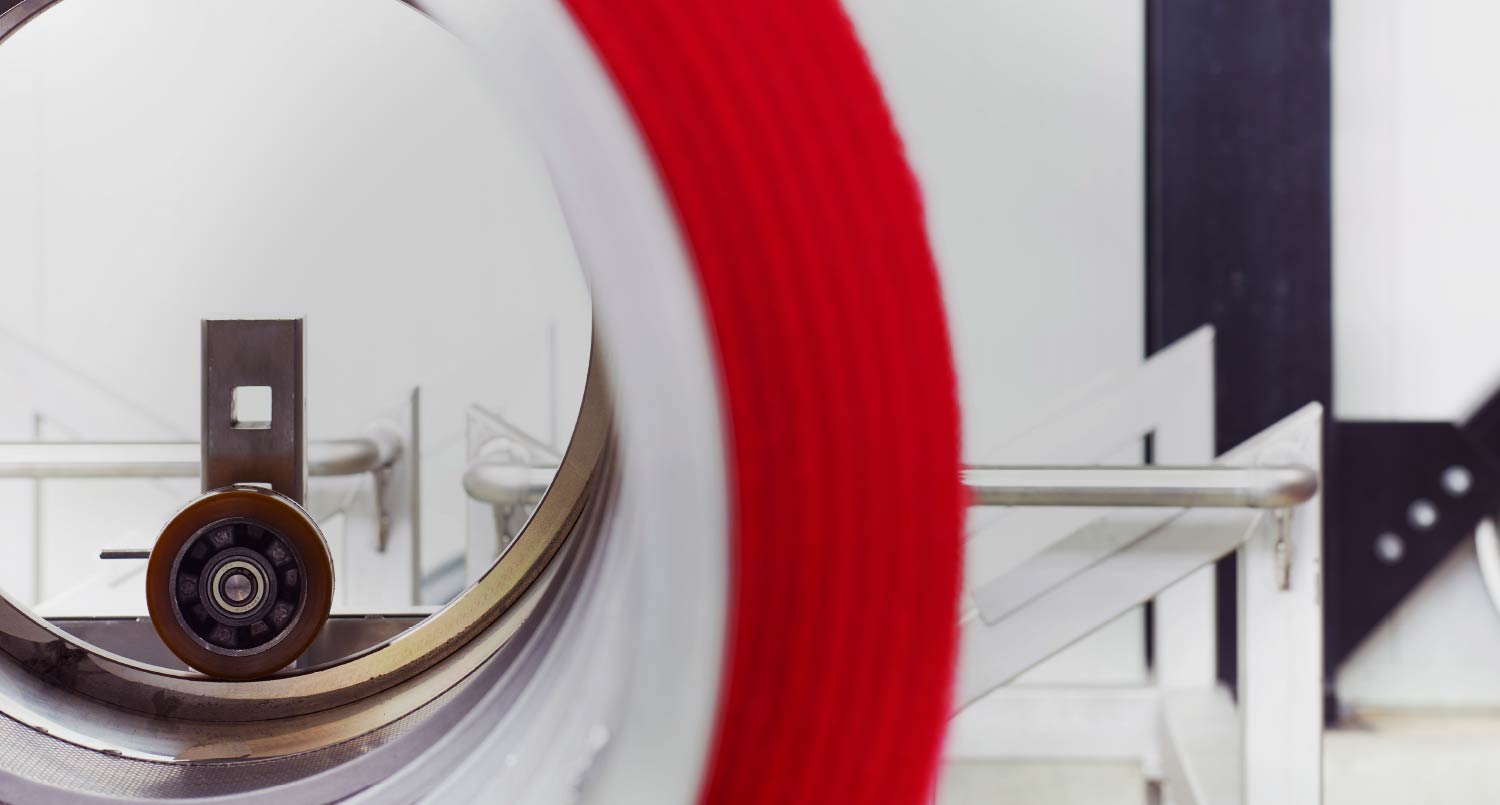

Wool scouring in process, mini scale 'siroscour' scouring system

Freshly shorn merino wool contains natural lanolin (wool grease), dirt, sweat (suint), and organic debris, and must undergo a specialized washing process called scouring to become clean and soft. Scouring takes place in large industrial lines—sequences of washing tanks filled with warm water and biodegradable detergents. In the pre-wash stage, wool is agitated in water heated to 40–60°C to dissolve suint and loosen dirt. It then moves through several main scouring baths where eco-friendly detergents remove lanolin. Afterward, the wool is rinsed with pure water to eliminate any chemical residue and then gently dried in warm air tunnels to protect the fiber structure and prevent felting. The result is fluffy, clean wool, ready for further refinement.

Raw wool is fed into the machine at one end, and by action of the rollers the fiber is combed and straightened.

After scouring, raw Merino wool remains in a tangled, matted form and must be refined into a smooth, spinnable material through a process called carding. In this step, the wool is fed into large drum carding machines equipped with thousands of fine wire teeth that gently pull, straighten, and separate the fibers into a soft, uniform sheet. During this process, shorter fibers are removed, leaving only long, high-quality strands—an essential factor for creating strong, smooth yarns. The aligned fibers are then drawn into thin, rope-like strands called slivers, which are ideal for spinning. Carding is critical because itensures the consistency and evenness of the fiber, eliminating weak points that could lead to pilling or breakage in the final fabric.

In both images the threads are drawn from the carded rolls and are twisted into yarn.

Spinning is one of the most critical steps in Merino wool production—it determines the strength, stretch, and overall performance of the final fabric. For Foehn, the wool is spun into core-spun yarn, where Merino fibers are wrapped around a durable nylon filament to enhance longevity without compromising softness. The process begins with drafting, where the carded slivers are stretched into thinner strands. These strands are then twisted to form continuous yarn. The twist level is carefully controlled: just enough to bind the fibers for durability, but not so tight as to compromise softness. During core-spinning, the ultrafine Merino is wrapped around a strong, lightweight nylon core. This construction significantly increases strength, reduces pilling and wear, and ensures that 100% Merino wool remains on the outside, next to your skin.

Circular knitting frame, via CSIRO (Creative Commons)

Once the Merino yarn is spun, it’s ready to be transformed into fabric through knitting, a process that defines the fabric’s weight, stretch, and durability. Using circular knitting machines, the yarn is looped into interlocking rows to create continuous lengths of fabric. These machines can produce different knit structures depending on the intended use. Jersey knit creates in a soft, stretchy, and breathable fabric, while Interlock knit, creates a thicker, double-layered construction. The density of the knit, measured in grams per square meter (GSM), determines how light or heavy the fabric feels.

Once knitting is complete, the raw, undyed fabric—known asgreige—is dyed and finished as needed. This might include softening, washing, or steaming treatments to enhance hand feel and durability. The result is a premium Merino fabric that’s ready to be cut, sewn, and transformed into high-performance garments.

This is the old spinning wheel, once in use in nearly every farmhouse, where they raised their own wool, spun their own yarn and made their own cloth with a hand loom.

Fine-tuned by nature for softness and adaptability, enhanced by technology for strength and stability. From its meticulous processing journey to the science behind its comfort, ultrafine merino is a fusion of tradition and innovation. Few materials can match merino wool’s unique combination of warmth, breathability, odor resistance, and sustainability. As the industry continues to refine spinning techniques and sustainable practices, merino wool’s role in high-performance apparel is only growing, solidifying its status as a gold standard for natural technical fabrics.

Merino wool’s fineness is measured in microns (μm), which are microscopic units of fiber diameter. A lower micron count means a thinner fiber—and typically, a softer fabric. At 17.5 microns, Merino fibers are classified as fine and feel exceptionally soft. In contrast, coarser wools above ~30μ have larger, stiffer scales that can prick the skin, causing the familiar “itch” of old-fashioned wool.

Beyond softness, 17.5μ Merino wool brings a suite of natural performance benefits that make it ideal for activewear and all-day wear. Compared to other materials (both traditional wool and synthetics), fine Merino excels in regulating comfort:

• Thermal Regulation:Merino keeps you comfortable in a wide range of temperatures. Its natural crimp structure traps air to insulate in cold weather, while in warmth it releases excess heat and moisture.

• Moisture Wicking:Each fiber can absorb about 30% of its weight in water internally without feeling wet. As you sweat, Merino pulls moisture away from your skin into the fiber core, then allows it to evaporate slowly. This keeps you dry and comfortable during exercise.

• Odor Resistance:Merino’s protein-based fibers naturally inhibit bacterial growth and can absorb odor molecules. You can wear a Merino wool shirt for multiple workouts or long travel days without it stinking.

• Softness & Comfort:Unlike traditional wool sweaters, a 17.5-micron Merino garment is ultra-soft and smooth on the skin. The tiny diameter of the fibers means they bend easily and don’t prick the skin’s nerve endings.

• Durability & Easy Care:Modern Merino knits are often machine-washable, and because wool resists dirt and stains, Merino garments don’t require frequent washing. Simply airing them out is usually enough to freshen them up.

In summary, 17.5-micron merino wool represents the pinnacle of natural fiber engineering – fine-tuned by nature for softness and adaptability, and now enhanced by technology for strength and stability. From its meticulous processing journey to the science behind its comfort and the ethics of its production, ultrafine merino is a fusion of tradition and innovation.

Few materials can match merino wool’s unique combination of warmth, breathability, odor resistance, and sustainability. As the industry continues to refine spinning techniques and sustainable practices, merino wool’s role in high-performance apparel is only growing, solidifying its status as a gold standard for natural technical fabrics.