When we talk about fabrics, most people picture the finished cloth—your jacket, a pair of pants, something you can touch. But every textile starts much earlier, with yarn. And yarn is more than just a strand of fiber; it’s an engineered structure built to perform in specific ways.

Understanding yarn means looking closely at three core attributes that designers and engineers play with: twist, tenacity, and tension. Each of these factors changes how a fabric behaves, and together they shape everything from the drape of a summer shirt to the durability of a pair of climbing pants. In technical apparel, these subtle yarn choices can make the difference between gear that fails and gear that excels.

The Spinning Jenny, invented in the 1760s by James Hargreaves, was a multi-spindle spinning frame that revolutionized textile production by allowing one worker to spin several yarns at once, dramatically increasing efficiency.

Yarn isn’t simply loose fibers lying together – twist is what binds those fibers into a coherent thread. By twisting fibers, we give yarn its structure and much of its strength. How tightly (or loosely) the yarn is twisted is like a hidden architecture within the fabric, influencing softness, stretch, and resilience. Here’s how twist levels affect yarn:

Twist binds drafted fibers together, transforming loose strands into yarn

Low Twist: A low-twist yarn has fibers that are only gently spun together. The result is a soft, fluffy, and airy yarn. Fabrics made from low-twist yarn tend to feel plush and breathable, with a friendly drape that flows. Think of a cozy knit sweater or an insulation layer – the yarn is often low-twist to trap air (for warmth) and to feel cushy. However, low-twist yarns are not very tight, so while they’re soft, they can be a bit less strong or durable. You’ll find low-twist constructions in garments where comfort and warmth are key, not hardcore abrasion resistance.

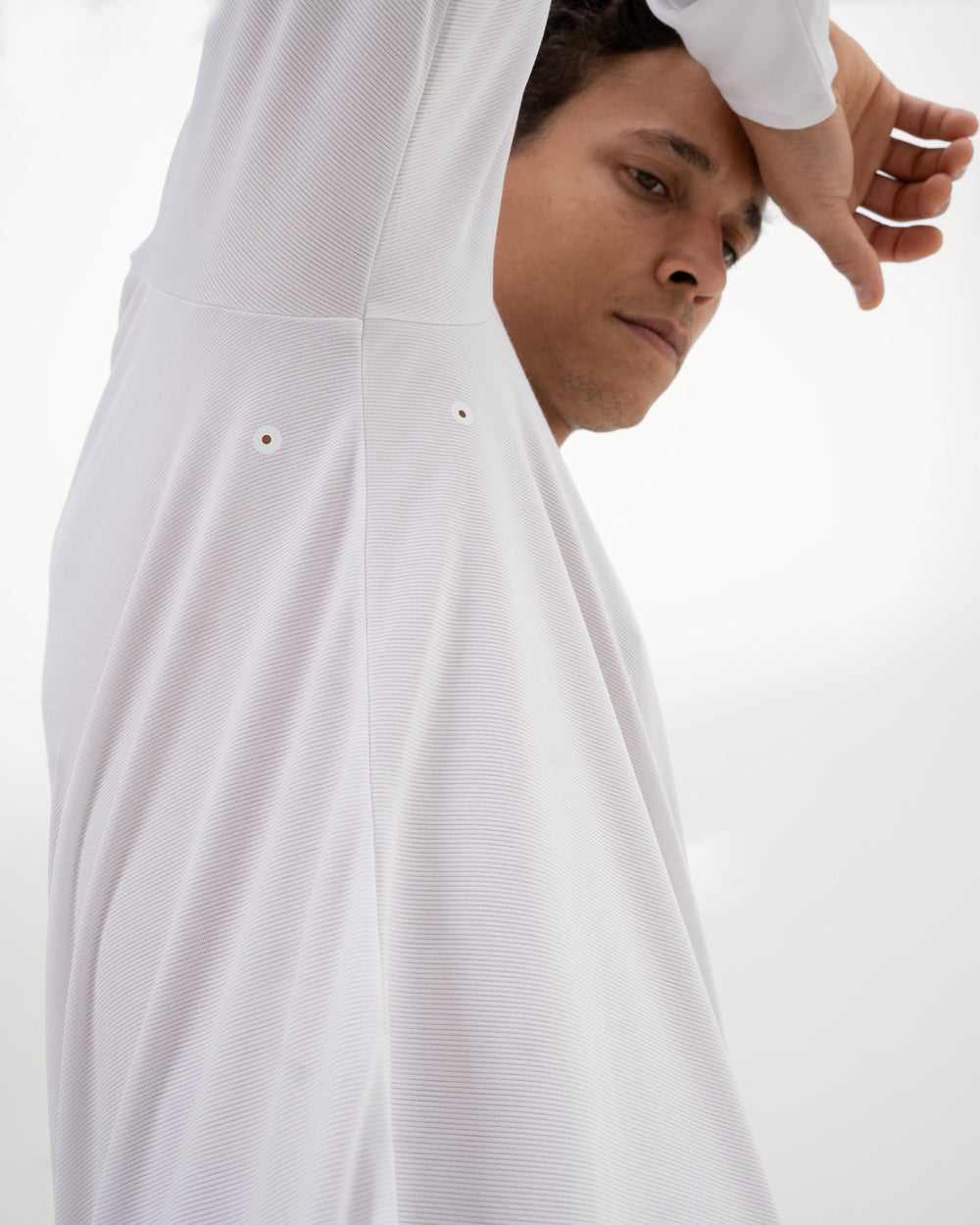

High Twist: A high-twist yarn is spun very tightly, packing the fibers together densely. This produces a smoother and thinner yarn with a firm feel. Fabrics using high-twist yarn come out crisp, strong, and abrasion-resistant. They have less fluff, so they feel sleeker to the touch and often have a slight lustrous sheen. High twist gives the yarn a built-in springiness and “memory,” meaning it recovers its shape better after stretching – your technical shirt or hiking pants won’t bag out as easily. The trade-off is that high-twist fabrics can feel a bit stiffer with less of the flowing drape; they tend to be more structured. This twist level is perfect for hard-wearing gear like climbing pants or a durable outdoor shirt, where you want the fabric to resist wear and hold its shape.

Twist is essentially the yarn’s internal architecture, and tweaking it has been a quiet driver of innovation in textiles for centuries. Historically, twist has been the difference between a delicate homespun yarn and a robust industrial one. From hand-spun wool yarns of ancient times to modern high-tech spinning on air-jet machines, controlling twist has allowed makers to tune fabrics for purpose. Imagine old sailcloth versus fine lace – much of that difference came down to how tightly the fibers were twisted. In short, twist can turn the same fiber into either a fragile, soft thread or a tough, long-lasting one. It’s a lever that inventors and engineers have pulled again and again to get the performance they need.

Spinning is where fibers become yarn. It’s not one step, but a balance of two happening at once: drafting (fibers are drawn out and thinned) and twist (fibers are locked together into a continuous strand). The force applied during this process — tension — is what keeps everything under control.

If tension is too high, fibers are pulled too aggressively. The yarn comes out thin, wiry, and more likely to snap. Too low, and the fibers drift without enough alignment, leaving the yarn weak, lumpy, or uneven. The right balance holds fibers steady as twist sets in, producing yarn that is uniform in thickness, consistent in strength, and reliable in performance.

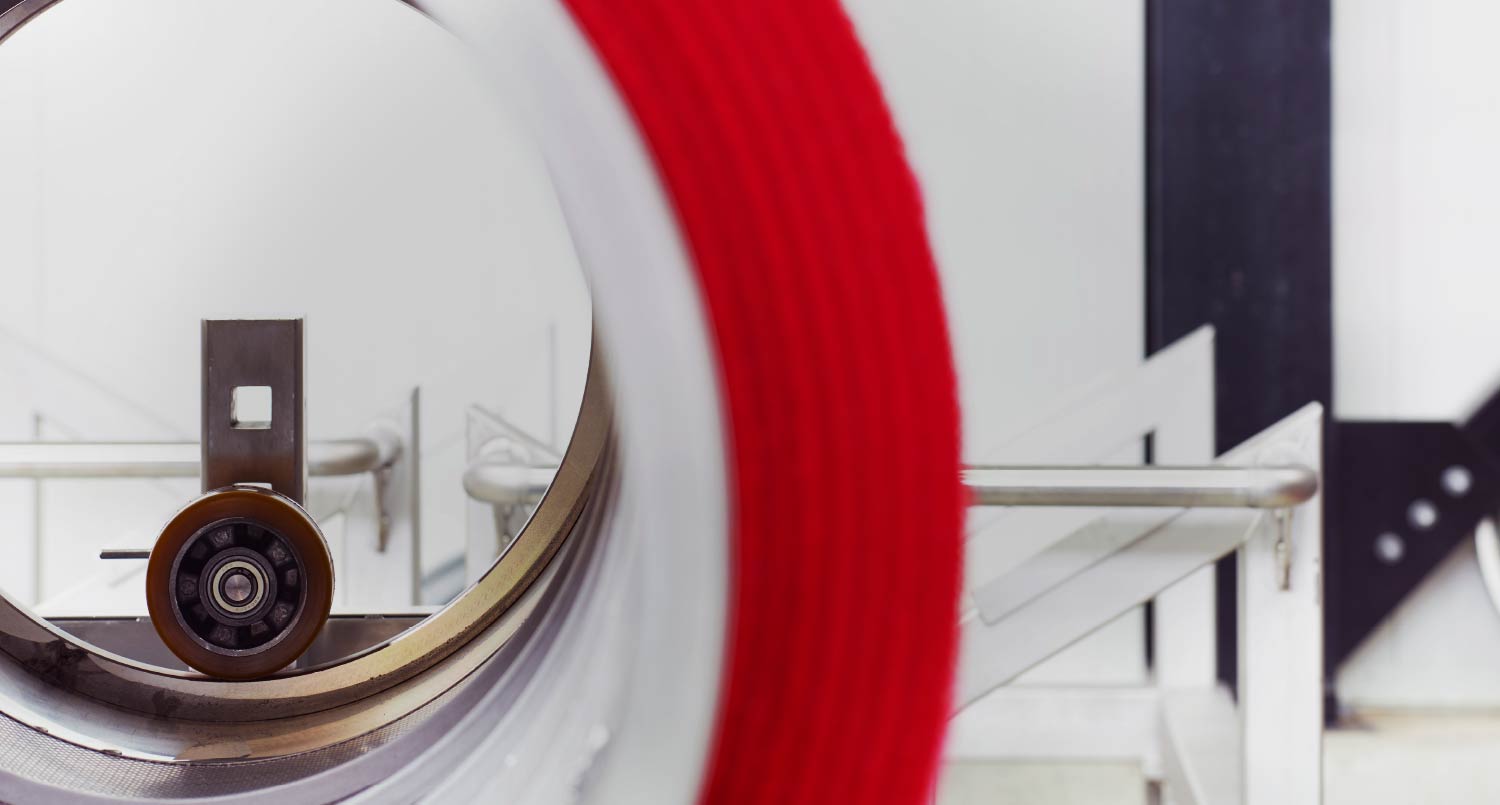

In ring spinning, the ring guides the yarn as it twists around the spindle, giving the process its name and signature strength.

Ring Spinning

Fibers pass through drafting rollers before being twisted around a spindle. Here, tension is managed almost entirely by the rollers, keeping fibers in line as twist builds. The result is smooth, strong, and highly uniform yarn — the reason ring-spun yarn is still the benchmark for durability and quality.

In open-end (rotor) spinning, fibers are fed into a fast-spinning rotor where twist forms instantly.

Open-End (Rotor) Spinning

Instead of a spindle, fibers are fed into a rapidly spinning rotor, where twist forms as they attach to the edge of the yarn tail. Tension is controlled by air flow and centrifugal force. It’s faster and more economical than ring spinning, but the yarn is bulkier and less strong. You’ll see it in denim, basic knits, and other fabrics where speed and cost outweigh fine performance.

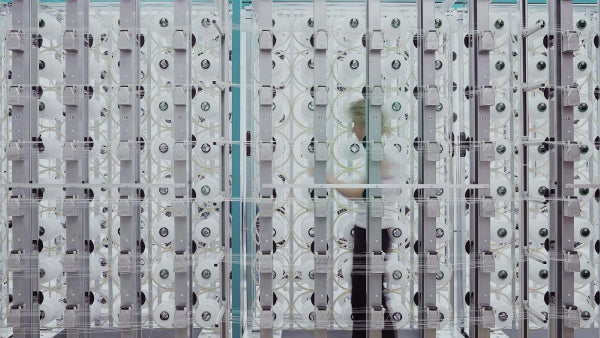

In air-jet spinning, high-speed jets of air wrap fibers into a smooth, consistent yarn.

Air-Jet Spinning

Fibers are drafted by rollers and then bound together by high-speed jets of air. Tension here is extremely stable, allowing for fast, consistent output. The yarn is smooth and even, but because the fibers are more wrapped than fully twisted, it isn’t as strong as ring-spun. Perfect for lightweight, comfortable fabrics where uniformity matters more than maximum abrasion resistance.

For performance apparel, tension in spinning isn’t a small detail — it’s the foundation of reliability. Yarns spun under controlled, balanced tension resist weak spots, pilling, and premature failure. Whether it’s a lightweight running shirt or a climbing pant, the way fibers were handled at the spinning stage decides how the fabric will perform years down the line.

Before spinning begins, compact cotton bales are opened and cleaned, turning packed fiber into a uniform feed for roving.

Tenacity is a measure of strength – specifically, how much pulling force a yarn (or the fiber in it) can withstand before it breaks, relative to its weight. Think of it as tensile strength per unit of size. A high-tenacity yarn is incredibly strong for its weight, while a low-tenacity yarn might snap or tear more easily under stress. This property starts with the fibers themselves and varies widely between materials.

Natural Fibers: In natural fibers like cotton, wool, or silk, tenacity comes from the fiber’s biology. Cotton fibers, for example, are made of cellulose arranged in microscopic structures; wool is made of protein (keratin) with a coiled structure. These intrinsic make-ups set a limit on strength. Natural fibers often have moderate tenacity – enough for everyday use, but they can only be as strong as nature made them. For instance, a strand of wool yarn will break under less force than an equally thick strand of nylon because wool’s internal bonds are not as high-strength as nylon’s. (Interesting fact: cotton actually gains strength when wet, which is one reason it’s been a reliable workwear fiber, whereas something like rayon weakens when wet. Each natural fiber has its own quirks.)

Synthetic Fibers: In synthetic fibers (like nylon, polyester, aramid, etc.), tenacity is engineered during production. Chemists and material scientists design these fibers at the molecular level to achieve high strength-to-weight ratios. Nylon was a game-changer when it was introduced: by weight, its tensile strength can rival that of steel wire. This is why early nylon replaced silk in products like parachutes – it could handle the shock loads of a parachute opening, with far less weight and bulk. Modern examples include high-tenacity nylon or polyester yarns used in outdoor gear; these are made by drawing and aligning the polymer chains to pack them with strength. The result is yarn that can take a beating: you can have a relatively thin synthetic fabric that you cannot break easily with your hands, which is astounding if you think about it. There are even super-fibers (like aramids such as Kevlar, or ultra-high-molecular-weight polyethylene like Dyneema) that push tenacity to extremes for use in bulletproof vests or climbing ropes. But even in everyday apparel, using a higher-tenacity variant of nylon or polyester means the garment can be much tougher without being heavier.

In the performance apparel world, tenacity is what determines whether your jacket or pants can survive real-world abuses: the friction of a heavy backpack strap, the repeated bending of knees and elbows, scrapes against rock or rough surfaces, and the general strain of movement. A fabric made with low-tenacity fibers might feel fine at first, but it could fail or wear through much sooner under those stresses. Tenacity at the fiber level is like a safety margin engineered into every thread of the fabric.

Yarn is not an afterthought – it’s the foundation. By the time you see a finished jacket or pant, there have been dozens of decisions made about the yarn that went into it. Products don't perform well because of some high-tech brand name; they perform because of the yarns engineered inside that fabric and how they were spun and woven. The difference between a pant that comfortably stretches with your movements versus one that bags out and sags after a few uses, or the difference between a shirt that breathes in hot weather versus one that feels like clingy plastic – often comes down to choices made at the yarn stage: the twist level used in the yarn, the tenacity of the fiber chosen, and the tension control during knitting or weaving, all long before the garment is ever cut and sewn.

Every thread in your apparel carries invisible design decisions that translate directly into how you experience that product: how you move in it, how it handles the stresses of your adventures, and how long it lasts in your wardrobe.