Before warmth, there's structure

Every down jacket is built on a simple idea: trap warm air, keep cold out. But the way that insulation is held in place — the actual construction of the jacket — can dramatically change how well it works. That’s where baffles come in.

Baffles are the chambers or compartments that hold down in place. Without them, the insulation would clump, shift, and leave cold spots. Baffles keep the down evenly distributed — and help the jacket stay warm, lightweight, and breathable.

There are a few common types, each with trade-offs in warmth, weight, and manufacturing complexity.

Stitched-Through Baffles

This is the most recognizable baffle construction method. In a stitched-through design, the outer and inner fabric layers are sewn directly together, creating a quilted pattern of narrow channels or boxes. Each chamber is then filled with down, which lofts to trap warm air within these stitched compartments.

Because the stitching runs all the way through the jacket, it compresses the insulation along the seam lines. That compression reduces loft in those areas, which can lead to thermal bridging — localized cold spots where heat escapes more easily.

Despite that drawback, stitched-through construction has a major upside: it’s incredibly lightweight and compact. With fewer internal materials, jackets built this way are more compressible and breathable, making them ideal for high-output activities or for layering under a shell in variable conditions. It’s also a simpler manufacturing process, which helps keep the cost and weight down.

Best for: Lightweight down jackets, midlayers, and pieces intended for aerobic movement or shoulder-season use.

Key traits:

✔ Streamlined silhouette

✔ Fast packability

✔ Less bulk, more motion

✘ Not designed for sustained exposure to deep cold

Box-Wall Baffles

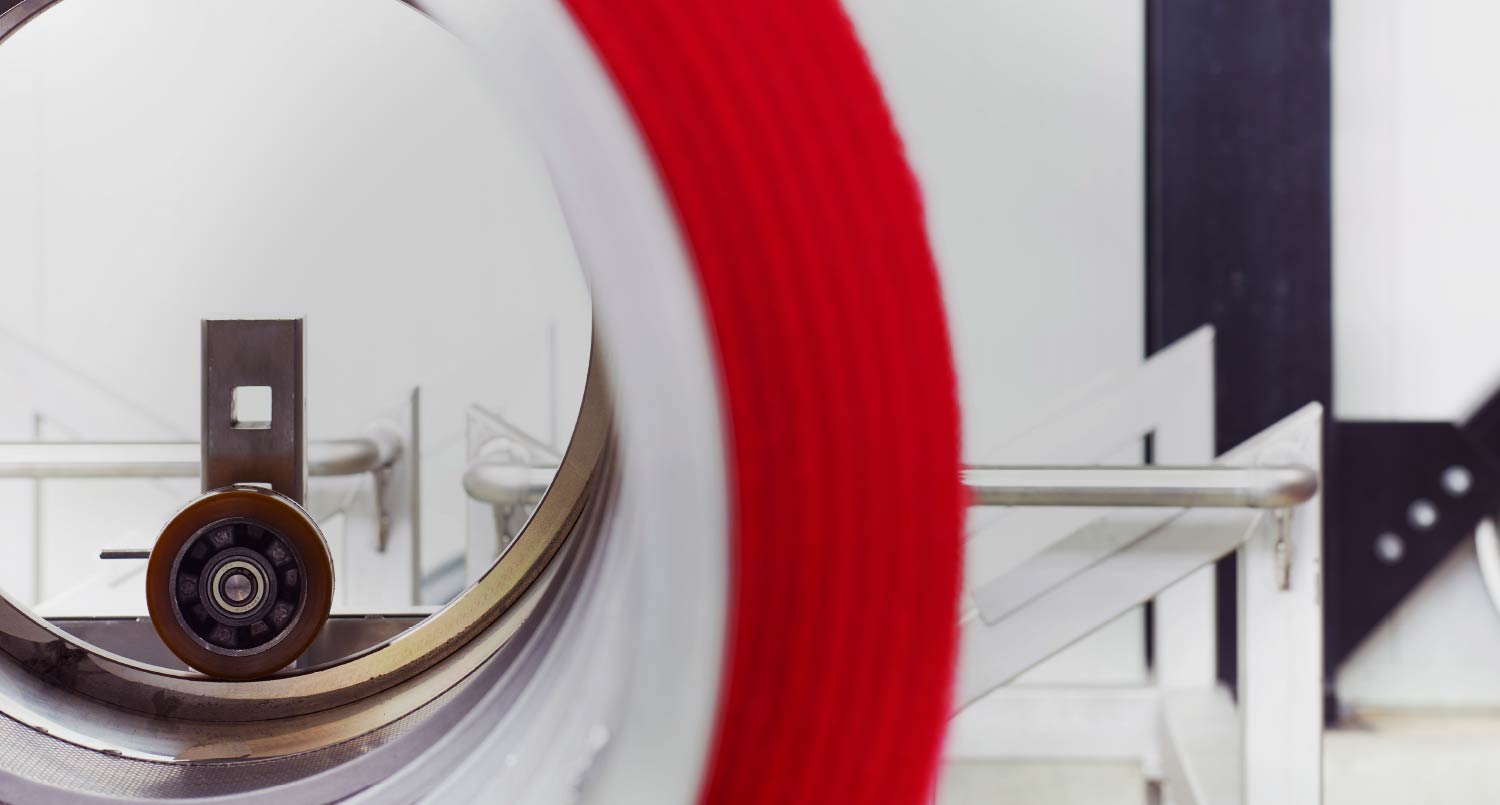

Box-wall (or box-baffle) construction is a more advanced method designed to maximize thermal efficiency. Instead of stitching the outer and inner fabric layers directly together — as in stitched-through designs — a third piece of fabric is sewn between them, forming a rectangular wall. This creates a true box-shaped chamber for the down to fully loft, with no compression points at the seams.

The result? No cold spots. Each compartment allows the insulation to expand to its full potential, providing consistent warmth across the surface of the garment. With space to loft evenly, the down traps more air — and more air means more warmth.

Box-wall construction is typically reserved for pieces designed for sustained exposure to extreme cold. It’s commonly used in expedition parkas, high-altitude belay jackets, and insulated outer layers meant for alpine environments or polar conditions. That added warmth comes at a cost, though: these jackets are heavier, bulkier, and more expensive to manufacture due to the complexity of the internal structure.

Best for: High-loft expedition jackets, big-wall belay parkas, winter mountaineering gear, and conditions where warmth trumps weight.

Key traits:

✔ Maximum loft = maximum warmth

✔ No cold spots

✔ Engineered for serious cold

✘ Bulkier silhouette

✘ Heavier and less packable

Offset or Overlapping Baffles

Offset baffle construction is a clever way to eliminate cold spots while keeping a relatively streamlined profile. Unlike stitched-through baffles — where insulation is compressed at every seam — offset baffles stagger those seam lines between the outer and inner fabric layers. This means that the inner and outer stitching lines never directly align, so there’s always a layer of down between your body and the outside air.

Imagine it like brickwork: the seams on one layer are “covered” by the insulation-filled chambers of the other. That overlap maintains continuous warmth and reduces the risk of thermal bridging.

This technique is most commonly used in sleeping bags, where thermal efficiency is paramount and you can’t afford to have cold spots. But some high-performance jackets—especially those designed for alpine or expedition use—adopt offset baffles as a way to boost warmth without resorting to full box-wall construction.

The trade-off is added complexity. These garments require more precise internal alignment, more fabric, and longer assembly time, which can bump up cost and weight slightly.

Best for: High-efficiency sleeping bags, alpine belay jackets, and outer layers where warmth must be maximized without unnecessary bulk.

Key traits:

✔ No cold spots

✔ Excellent warmth-to-weight ratio

✔ Great for stationary cold

✘ More complex to construct

✘ Slightly heavier than stitched-through